•

Unscrew the plunger retaining cap

from the pump barrel by rotating the

handle.

•

Withdraw the plunger and apply

silicone grease to the O-ring.

•

When re-assembling ensure the O-ring

is not trapped between the outer edge

of the plunger moulding and the inside

of the pump barrel.

Pump non-return valve:

(situated at the bottom of the pump barrel)

•

This stops the compressed air in the

container from escaping back into the

pump.

•

If it is faulty, the unlocked pump handle

will rise when the container is

pressurised.

•

To remove the valve, lift the edge of

the valve and pull. ( take care not to

damage the sealing face of the barrel).

•

To replace, place the valve over the

centre hole and push down firmly.

Pump barrel sealing rings:

•

These make an air tight seal between

both the pump barrel and adapter;

•

Also between the adapter and

container when both are screwed

down tight.

•

To check this, turn the pressurised

sprayer upside down and if there is a

leak, liquid will be forced from the

joints.

Nozzle cap:

•

Keep this clean and free from

obstruction.

•

Also, the two swirl grooves at the end

of the lance must be kept clean and

free from sediment to ensure a good

spray pattern.

•

The nozzle O-ring should be kept

lubricated with silicone grease.

Lance:

•

Keep the trigger clean and free from

build up of sediment and chemicals by

regularly flushing through after use.

•

Of necessary remove and clean the

shuttle in the trigger.

Outlet and dip tube:

•

To rewash the outlet or replace the dip

tube, unscrew the hose nut and pull

the outlet spigot and dip tube through

the outlet body.

Winter use:

•

Drain liquid from all parts after use to

prevent damage from freezing.

Annual maintenance:

•

At least once a year thoroughly clean

the whole sprayer and apply silicone

grease to all moving parts.

•

Test with water and if any washer or

seal has perished it must be replaced.

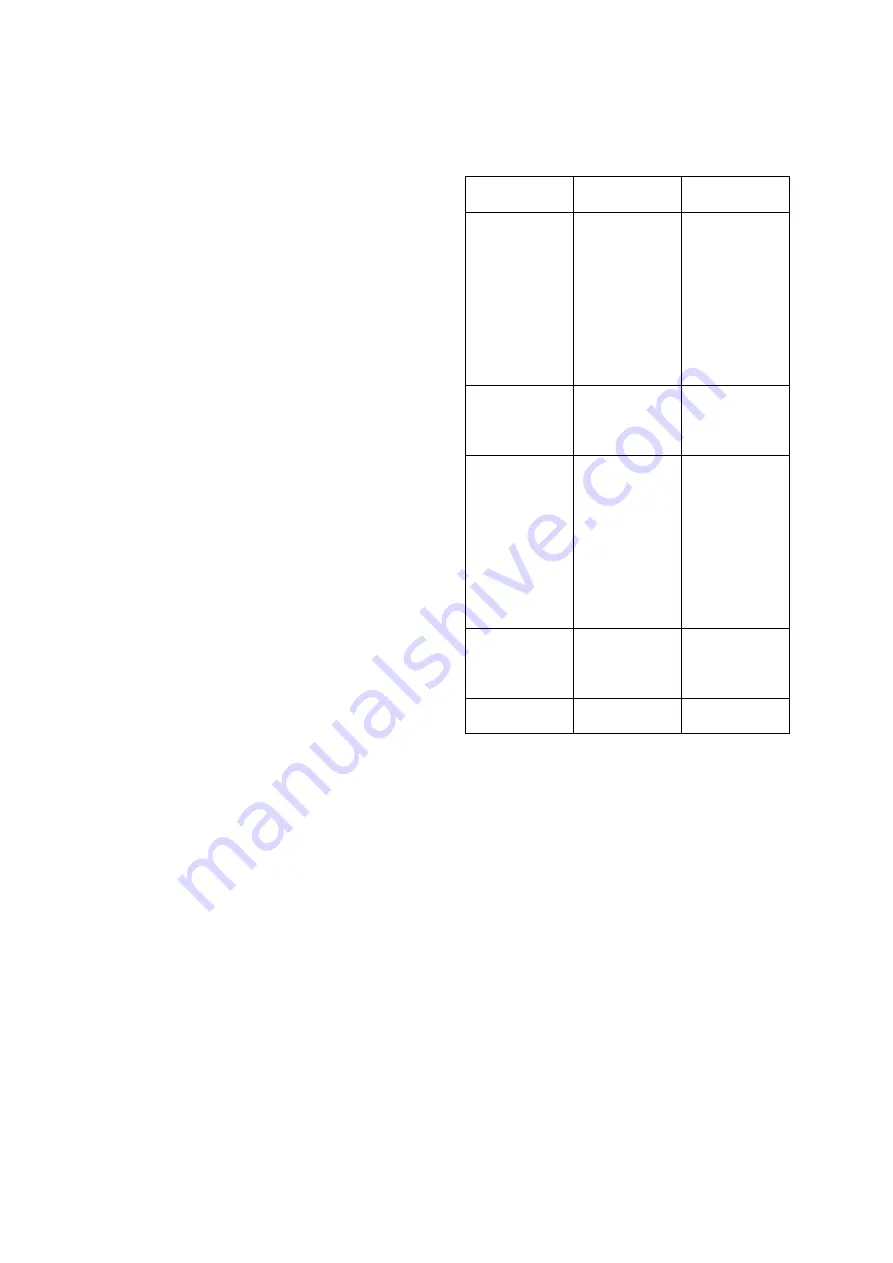

FAULT FINDING CHART

Fault

May be due

to

Remedy

Weak or no

spray

1. insufficient

pressure or

loss of air

2. obstruction

1. if

insufficient

pressure

check

maintenance.

2. if

obstruction

check

maintenance.

Distorted

spray

Partial

blockage in

spindle or

nozzle

Check

maintenance

Leaks

1.build up of

sediment or

foreign

matter on

internal

sealing

surfaces

2. split

sealing ring.

1. check

maintenance

and if

necessary

replace

sealing rings.

2. replace

sealing rings.

Unit will not

function

Swelling of

sealing rings

or total

blockage

Check

maintenance.

Handle rises

Faulty non-

return valve

Check

maintenance

GUARANTEE

Refer to the enclosed guarantee conditions for

the terms and conditions of guarantee.

ENVIRONMENT

Should your machine need replacement after

exceeded use, do not put it in the domestic

waste but dispose of it in an environmentally

safe way.