45

45

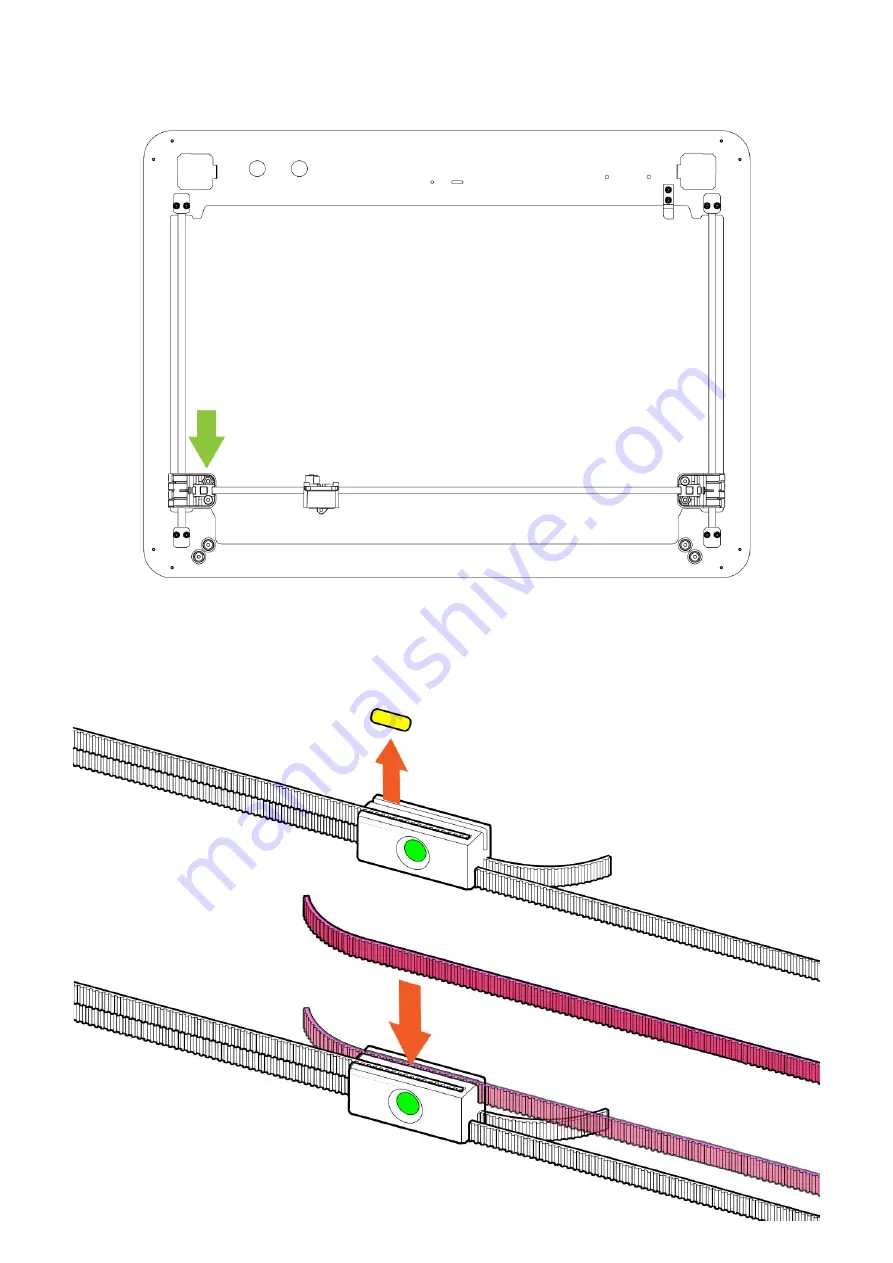

Remove the yellow belt tab and and press the

Belt into the Belt Hub as shown in the diagram.

Pull the belt tight. This should cause the left hand side

Gantry Carriage to get closer to the Top

Panel.

Apply just enough tension to the belt to remove the gap between the left hand side

Gantry

Carriage and the Top Panel.

Summary of Contents for Emblaser Core

Page 1: ...Emblaser Core Assembly Manual Rev 1 32 User Assembly Manual English Darkly LabsR Kit Rev 1 0 ...

Page 13: ...Step 1 04 Place the 4x Cable Management Clips in the recesses on the Rear Panel 13 ...

Page 21: ...21 Step 2 06 Assemble the four Idle Pulleys ...

Page 33: ...33 33 Step 2 16 Route the Belt around the two Lower Position Idle Pulleys as shown ...

Page 35: ...35 35 Step 2 18 Route the Belt behind lower position pulley in the Gantry Carriage ...

Page 41: ...41 41 Step 2 22 Route the Belt around the two Upper Position Idle Pulleys as shown ...

Page 42: ...42 42 Step 2 23 Pass the Belt through the Gantry Carraige and around the Motor Pulley ...

Page 43: ...43 43 Step 2 24 Route the Belt behind lower position pulley in the Gantry Carriage ...

Page 52: ...Fold the Driver Board Cover as shown in the diagram Step 3 07 52 52 ...

Page 68: ...Attach the Rubber Feet to the Base Plate as shown below Step 8 03 68 68 ...

Page 76: ...Connect Workspace Camera cable to the Controller Board socket indicated Step 03 76 76 ...