P1

P2

-1

-2

-3

-4

-5

-6

-7

-1

-2

MOTOR

A1

A2

AC

AC

-1

-3

-4

-5

-6

-9

-10 -11 -12 -13

-36M / -3

8

M

OPTION

BOARD

530B

SERIES

BOARD

SPEEDPOT

LO

WIPER

HI

P4

P5

-36M / -3

8

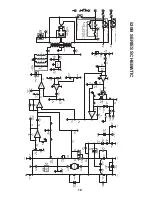

M HOOK-UP FOR UNIDIRECTIONAL RUN / DYNAMIC BRAKE

REV

-1

-3

-2

COM

FWD

NOTE:

INPUTS TO TERMINAL STRIP P5 CANNOT

BE REFERENCED TO EARTH

G

ROUND!

WHITE

BROWN

-7

-

8

SPST

SWITCH

CLOSED = RUN

OPEN = BRAKE

BLACK

-2

(-36M / -38M option continued)

FUSING

The motor and control are protected against overloads by the current limit circuit. Additional protection is provided through 2 fuses,

which are mounted on the main board. Use exact fuse replacements if the fuse requires changing. Before changing fuses, be sure

the power to the control is disconnected at the power source. Note: Both sides of VAC input are fused.

HP: 1/8 - 2.0 H.P.

FUSE SIZE: 20 Amp

FUSE TYPE: Bussman ABC-20 or Little Fuse 314020

HP: 3.0 H.P.

FUSE SIZE: 20 Amp

FUSE TYPE: Bussman ABC-20 or Little Fuse 314020

15

Warning:

The addition of this option no longer al-

lows for dual voltage operation of the 530B

series board. The 115/230 VAC input se-

lector switch (530B series board) must be

set for the proper VAC input rating of the

-36M/-38M option being used.

IMPORTANT:

DO NOT use JU2 jumper wire with this option.

When retrofitting, JU2 must be removed.

To identify JU2 jumper location, see “Basic

Hook-up Diagrams Without Options”.

IN CASE OF DIFFICULTY

PROBLEM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION(S)

Motor doesn’t operate

Armature output voltage

cannot be adjusted, out-

put is a constant DC level

Motor stalls or runs

very slowly with speed

control turned fully CW

Motor hunts

Repeated fuse blowing

Motor runs but will not stop

Replace fuse

Install proper service

Adjust speedpot CW to start

Replace motor brushes

See “JU2 Jumper Wire Selection Chart”

Check that the motor or load is connected

to Armature terminals

Check that speedpot low wire is connected

Should be above 104V or 208V

Reduce load or re-adjust Current Limit

Replace motor brushes

See “Adjustment Procedure”

See “Adjustment Procedure”

See “Adjustment Procedure”

Reduce Max trimpot setting

Reduce load

Relace motor brushes

Replace motor

Return for repair

Check “Terminal Strip Wiring” sections

Check wiring

Return for repair

Blown fuse

Incorrect or no power source

Speedpot set at zero

Worn motor brushes

Improper or missing jumpers

No motor or load connected

Speedpot low connection open

Low voltage

Overload condition

Worn motor brushes

Max. speed set incorrectly

Too much IR Comp

Motor is in Current Limit

Motor speed is above rated speed

Overload condition

Worn motor brushes

Defective motor

Failed electrical components

Incorrect wiring

Defective wiring

Failed component

After using this section, if control will still not operate, consult your Dart Distributor or Representative or return unit for repair.