CUR. LIM.

Limits DC motor armature current (torque) to prevent damage to the motor or control. The current limit is

set for 125% of the rated motor current. Clockwise rotation of this trimpot increases the armature current

(or torque produced).

1) Turn drive power OFF!

2) Connect a DC Ammeter in series with the +ARM line (bA on motor and +ARM on the control). Preset the

current limit trimpot CCW.

3) Turn power on and set speedpot to 50%.

4) Increase the motor load until the motor stalls (zero RPM).

5) Set CUR. LIM. trimpot by adjusting CW to 125% of the rated motor armature current (see “TRIMPOT CHART”).

ACCEL

Allows adjustment of acceleration by user.

1) Clockwise trimpot rotation increases length of acceleration time needed for the control to reach full speed.

DECEL

Allows adjustment of deceleration by user.

1) Clockwise trimpot rotation increases length of deceleration time needed for the control to reach zero speed.

8

(Adjustment procedure continued)

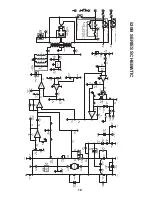

MIN ACCEL DECEL MAX I.R. CUR LIM HP VOLTS

1/

8

115

1/6 115

1/4 115

1/3 115

1/2 115

3/4 115

1.0 115

1/4 230

1/3 230

1/2 230

3/4 230

1.0 230

1.5 230

2.0 230

NOTES: These settin

g

s apply when usin

g

a 5000

Ω

speedpot. This chart cannot be used with certain Options (refer to Option section)

3.0 230

MIN ACCEL DECEL MAX I.R. CUR LIM HP VOLTS

1.5 115

TRIMPOT SETTING CHART

1.5 and 3.0 HORSEPOWER - MODEL 533BC

For 1.5 and 3.0 horsepower applications, the model 533BC control has the following restrictions:

●

Available in chassis (C) mount only.

●

The 1.5 horsepower model is available in 115 VAC input at 0-90 VDC out, while the 3.0 horsepower model is available in

230 VAC input at 0-180 VDC out.

●

Relay, start-stop, reversing, dynamic braking & jogging are not available from factory (they are customer supplied and wired).

●

The isolation boards (-5 and -7 options) are available.