Maintenance ■ Workspace, Head and Gantry

- 98 -

Data I/O ■ 096-0465-001C

Workspace, Head and Gantry

The workspace includes the Socket Adapters and items on the working

surface, but not the programmers. They are covered in a separate

heading.

Socket Adapters and Actuation

Under this heading you will learn about visually inspecting, cleaning and

adjusting sockets, actuation, and air pressure for the workspace items.

I

NSPECTING THE

S

OCKET

A

DAPTERS

The condition of the Socket Adapters has great throughput

consequences.

S

OCKET

L

IFE

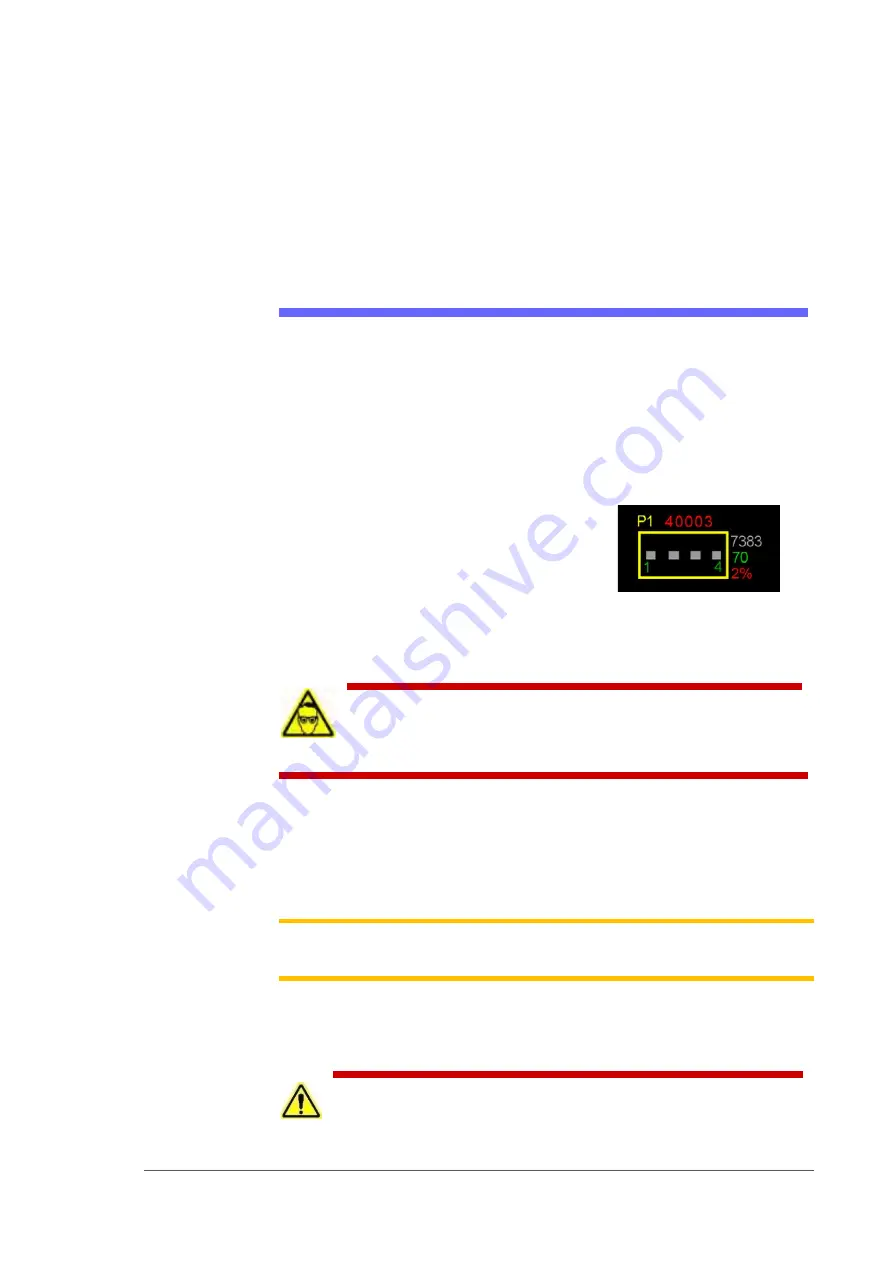

The Run window displays the Socket

Adapter lifetime actuation count in yellow

until it is exceeded at which time it changes

to red.

S

OCKET

C

LEANING

WARNING: Vision hazard! Pressurized air or debris blown into

the eyes or skin could cause bodily damage. Always use care and

wear protective eye goggles when cleaning with pressurized air.

1.

Use clean, dry compressed air (at 6.2 Bars (90 PSI or less) to remove

dirt from the sockets. Open and close the sockets while blowing them

out.

2.

Check the sockets for wear and replace if necessary.

Note:

The socket replacement cycle depends upon the type of socket used

and the socket manufacturer.

T

URNING

OFF

I

NPUT

A

IR

Prior to turning off the input air, ensure that no job is running.

CAUTION: Possible damage to programmers and devices! DO NOT

TURN AIR OR POWER OFF to the PSV5000 Machine while a job is

Summary of Contents for PSV5000

Page 12: ......

Page 36: ......

Page 160: ......

Page 161: ...Electrical Schematics for PSV5000 and Equipment ...

Page 162: ......

Page 163: ......

Page 164: ......

Page 165: ......

Page 166: ......

Page 167: ......

Page 168: ......

Page 169: ......

Page 170: ......

Page 171: ......

Page 172: ......

Page 173: ......

Page 174: ......

Page 175: ......

Page 176: ...PROGRAMMABLE MEDIA EXPERTS ...