■

Software

□

CH700 Application

PSV5000 Owner’s Manual

- 27 -

on our website under the SUPPORT tab. For more information, see

TaskLink online Help or Job Runner/Job Creator online Help.

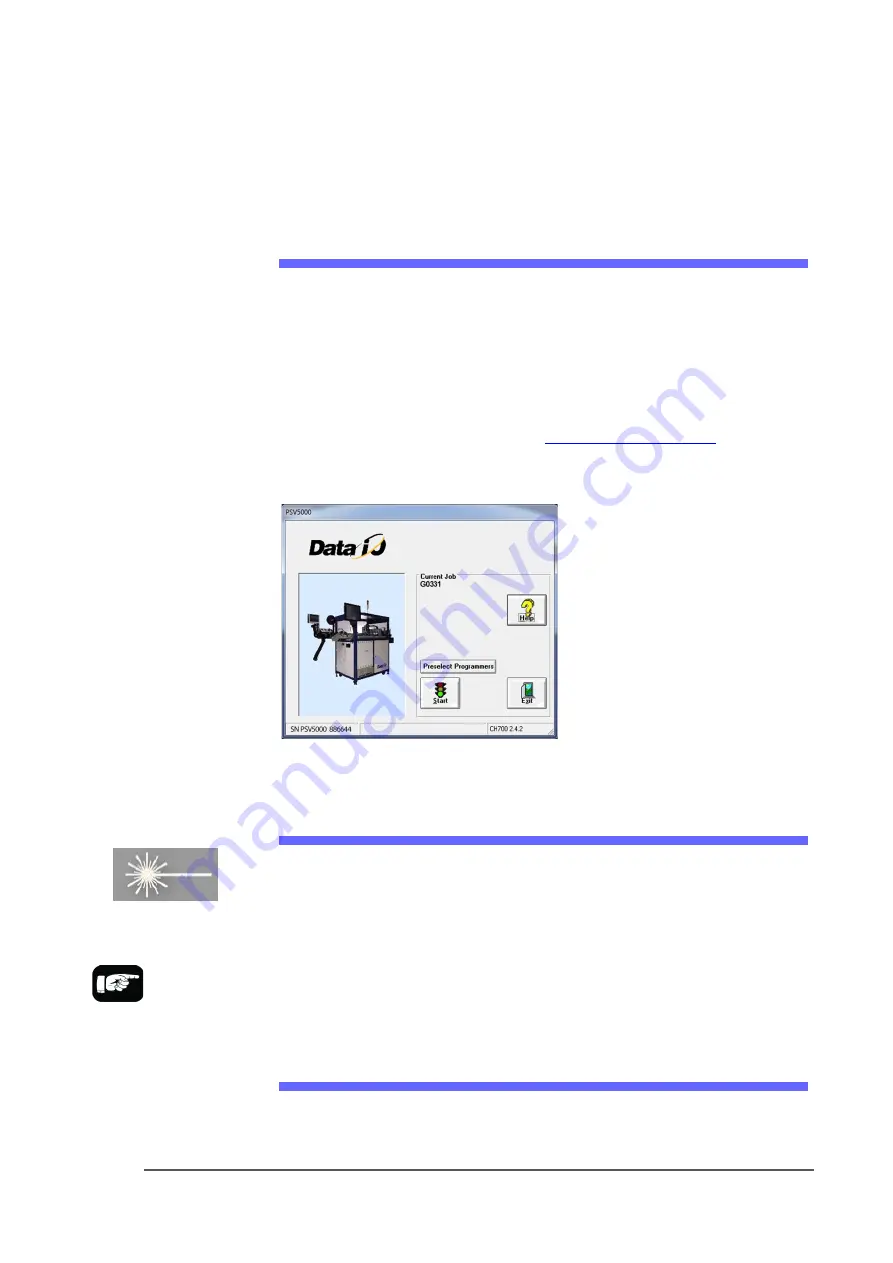

CH700 Application

Data I/O’s Automated Handler software is a Microsoft

®

Windows

®

-based

application for setting up and programming integrated circuits (devices)

on PSV5000 Systems. It offers a selection of many PSV5000 System

options such as input/output configurations, labeling options, and

statistical feedback methods. The CH700 application software resides in

the Handler Computer.

For updates to CH700 Software see

on our web

site under the SUPPORT tab. Then look for PSV5000 under

Download

the Latest Firmware

.

Figure 14:

CH700 Start-up window for PSV5000.

Laser Software

The Laser software is a Windows-based application that allows creating

parameters required for laser marking jobs as well as initiating laser

marking. This MarkingMate

software is on the Handler computer.

When the Laser Marking System is set up and initialized, it receives

commands from the CH700 which starts the marking sequence.

For more information please refer to the MarkingMate software help.

Laser Safety

The PSV5000 Laser option is designed in accordance with the following

safety guidelines:

For more information

about the Laser System,

see

Setting Up the Laser

Marking Module

on page

55 and

(Optional)

Creating a Laser Marking

File

on page 81.

Summary of Contents for PSV5000

Page 12: ......

Page 36: ......

Page 160: ......

Page 161: ...Electrical Schematics for PSV5000 and Equipment ...

Page 162: ......

Page 163: ......

Page 164: ......

Page 165: ......

Page 166: ......

Page 167: ......

Page 168: ......

Page 169: ......

Page 170: ......

Page 171: ......

Page 172: ......

Page 173: ......

Page 174: ......

Page 175: ......

Page 176: ...PROGRAMMABLE MEDIA EXPERTS ...