Ahiba IR Pro User's Guide

Index

•

47

Screen

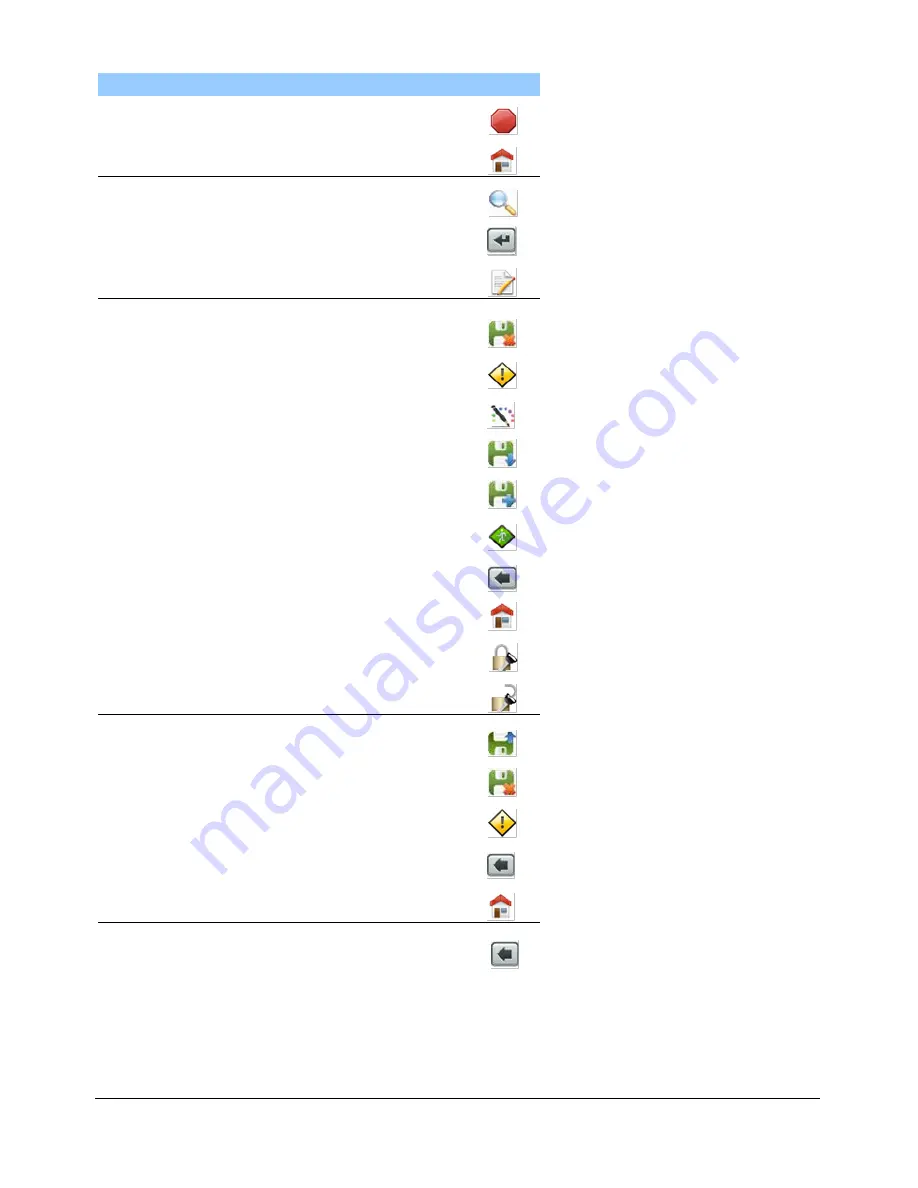

Icon Use

Icon

Manual mode screen

Stop manual program

Home Screen

Directory menu screen

View local Memory

View ext. Memory

View History local

View Local menu

Screen

Delete Program

Delete All Programs

Edit Program

Save External

Copy Program

Run Program

Previous screen

Home Screen

Login

Logout

View Ext. menu screen

Load ext. Memory

Delete Program

Delete All Programs

Previous screen

Home Screen

View history local

Previous Screen