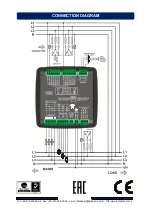

Although the unit is protected against

electromagnetic disturbances, excessive

disturbance can affect the operation,

measurement precision and data

communication quality.

Always remove the plug connectors

when inserting wires with

screwdriver.

Fuses of fast type with a maximum

rating of 6A must be connected to

the power supply and phase voltage

inputs, in close proximity of the unit.

Always refer to National Wiring

Regulations when conducting

installation.

Use cables of adequate current

carrying capacity (at least 0.75 mm

2

).

Use cables of adequed temperature

range.

Use at least 1.5mm

2

cables for

current transformer connection

(AWG15).

The current transformer cable length

should not exceed 1.5 meters. If

longer cable is used, cable section

must be increased proportionally.

Current transformers must have a

5A output.

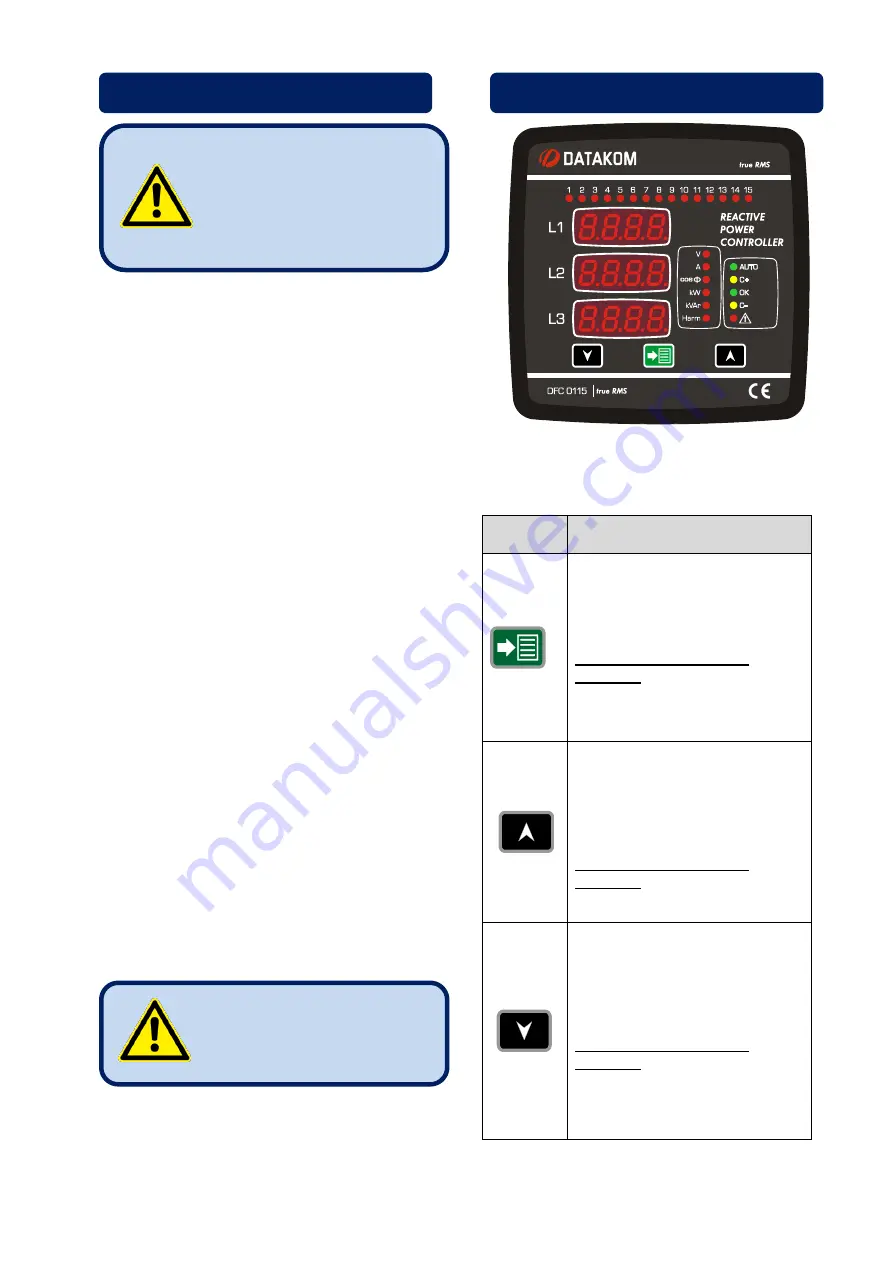

Three buttons on the front panel provide

access to configuration and measurement

screens.

BUTTON

FUNCTION

Remove all alarms in AUTO

mode.

If the same alarm occurs again,

it will not be displayed.

When held pressed for 3

seconds;

Programming mode activated.

All alarms are enabled.

Skip to the next parameter.

(Measurement and parameter

screen)

Increase related parameter.

(Programming screen)

When held pressed for 3

seconds;

Switch on and switch off steps.

Skip to the previous

parameter. (Measurement and

programming screen)

Decrease related parameter.

(Programming screen)

When held pressed for 3

seconds;

AUTO-MANUAL mode switch.

Reactive control is disabled at

MANUAL mode.

ELECTRICAL CONNECTIONS

Do not place the unit close

to high electromagnetic

noise emitting devices like

contactors, high current

busbars, switch mode

power supplies.

Do not overload relay

outputs. Use extra

contactors if required.

BUTTON FUNCTIONS