PRODUCT REFERENCE GUIDE 69

CHAPTER 5

TYPICAL LAYOUTS

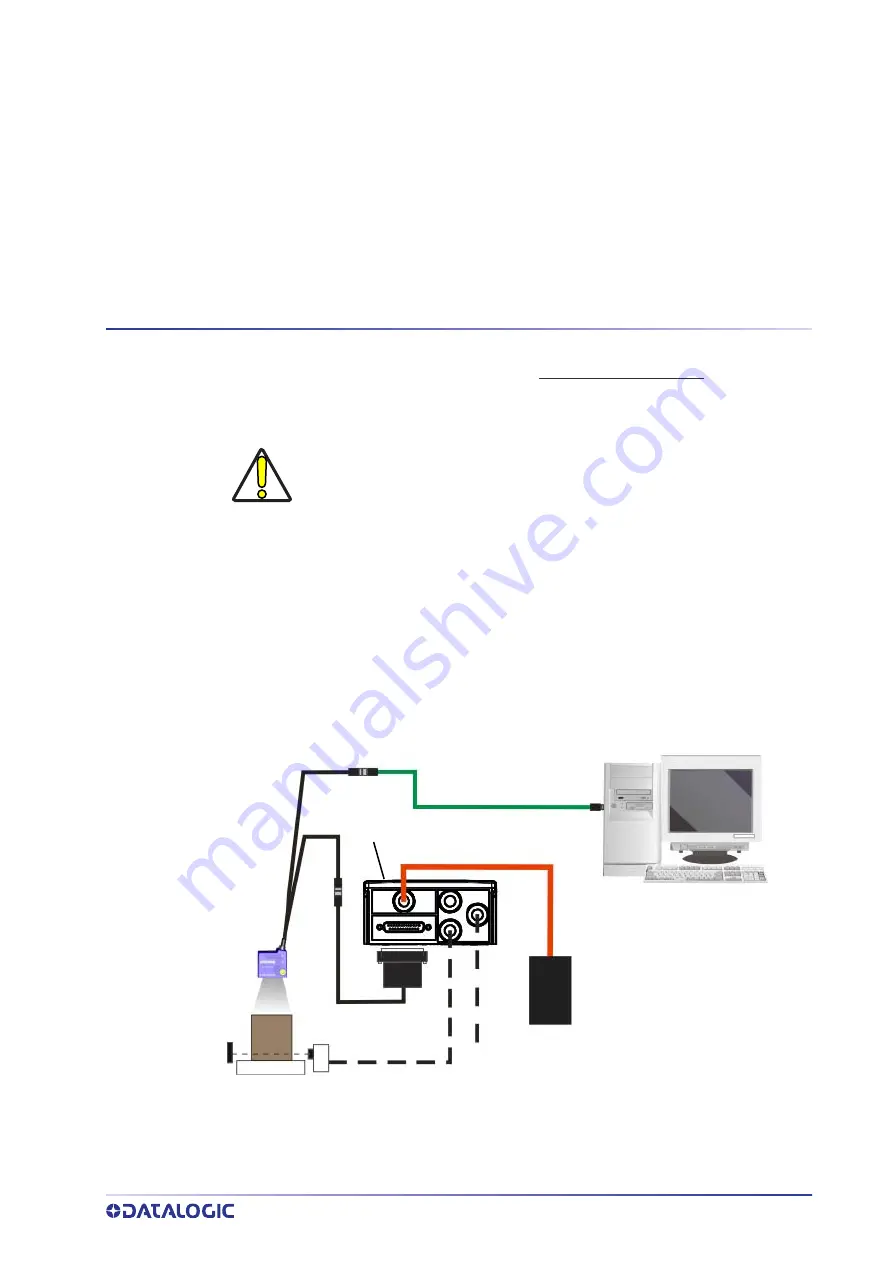

The following typical layouts refer to system hardware configurations. However, they

also require the correct setup of the software configuration parameters. Dotted lines in

the figures refer to optional hardware configurations within the particular layout.

ETHERNET CONNECTION

The Ethernet connection is possible in two different layouts.

In a Point-to-Point layout the reader is connected to a local host by using a

CAB-ETH-

M0x

cable. There is no need to use a crossover adapter since Matrix 120™ incorporates

an autocross function.

10-30 Vdc

Host

Matrix 120

CAB-ETH-M0x

CBX

Ethernet Interface

Auxiliary Serial Interface (Data Monitor)

External Trigger (for One Shot or Phase Mode)

CAB-1011

External Power for Matrix 120

and I/O Accessories

CAUTION

Matrix 120™ readers do not have Auxiliary Serial interfaces. Therefore,

neither data monitoring nor device configuration ca be performed

through this interface.

Matrix 120™ devices can be configured in DL.CODE through the Ether-

net, Main Serial, or USB interfaces depending on the device model.

Summary of Contents for 937800000

Page 1: ...Matrix 120 PRODUCT REFERENCE GUIDE Image Based Reader ...

Page 14: ...GENERAL VIEW XIV MATRIX 120 ...

Page 75: ...INPUTS PRODUCT REFERENCE GUIDE 61 Figure 41 NPN External Trigger Using Matrix 120 Power ...

Page 97: ...GLOBAL FOV DIAGRAMS PRODUCT REFERENCE GUIDE 83 Matrix 120 310 xxA Models Digimarc Barcode ...

Page 153: ...Reader 2 Reader 3 PASS THROUGH CONFIGURATIONS PRODUCT REFERENCE GUIDE 139 ...

Page 185: ......

Page 186: ......

Page 187: ......