CBX ELECTRICAL CONNECTIONS

39

4

4.2.2 RS485

Full-Duplex

Interface

The RS485 full-duplex (5 wires + shield) interface is used for non-polled communication

protocols in point-to-point connections over longer distances (max 1200 m / 3940 ft) than

those acceptable for RS232 communications or in electrically noisy environments.

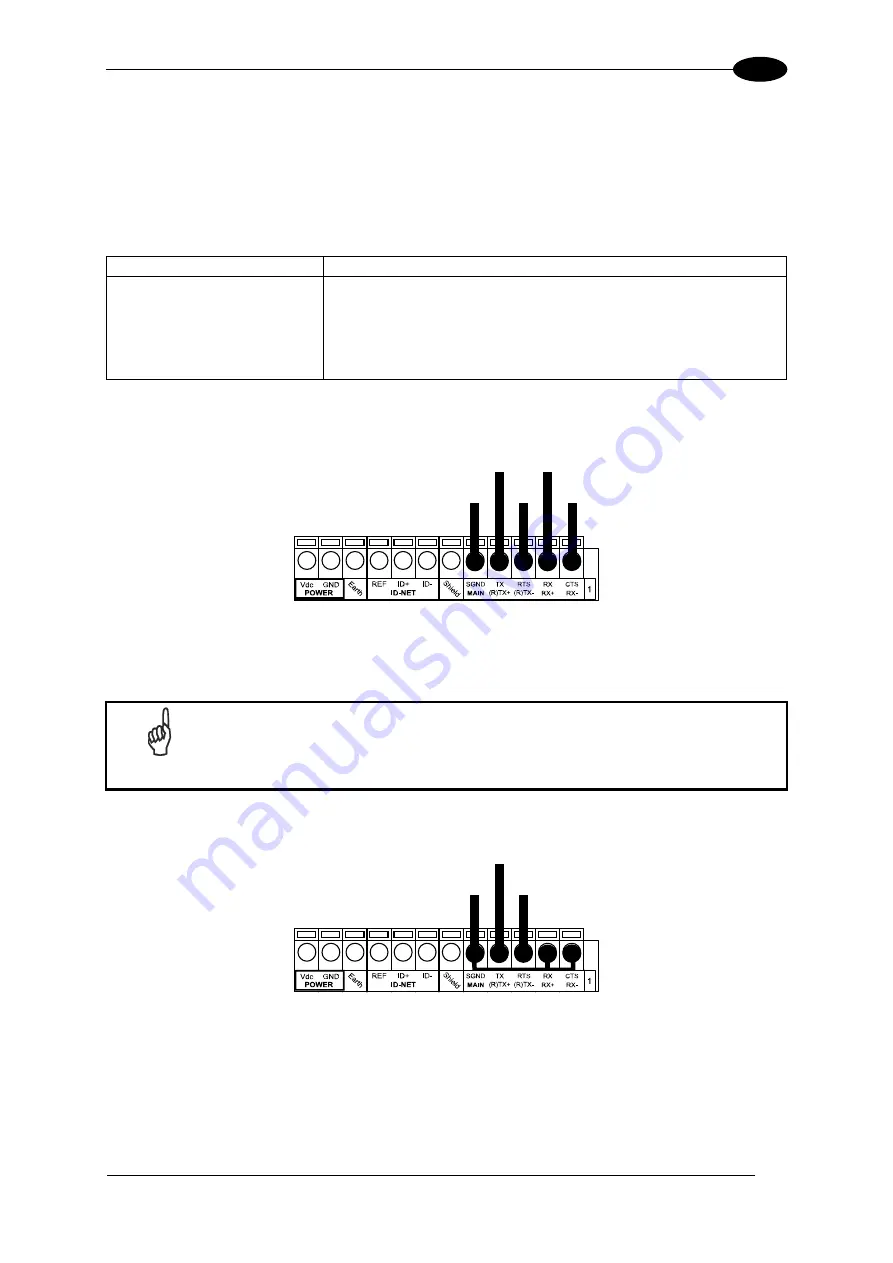

The CBX pinout follows:

CBX100/500

Function

TX+

RS485 Transmit Data +

RX+

RS485 Receive Data +

TX-

RS485 Transmit Data -

RX-

RS485 Receive Data -

SGND Signal

Ground

RX485+

TX485+

SGND RX485- TX485-

USER INTERFACE

SGND TX+

RX+

TX- RX-

SCANNER

Figure 41 - RS485 Full-duplex Connections

NOTE

For applications that do not use RX485 signals, do not leave these lines

floating but connect them to SGND as shown below.

RX485+

SGND RX485-

USER INTERFACE

SGND TX+

TX-

SCANNER

Figure 42 - RS485 Full-duplex Connections using Only TX Signals