READING FEATURES

4

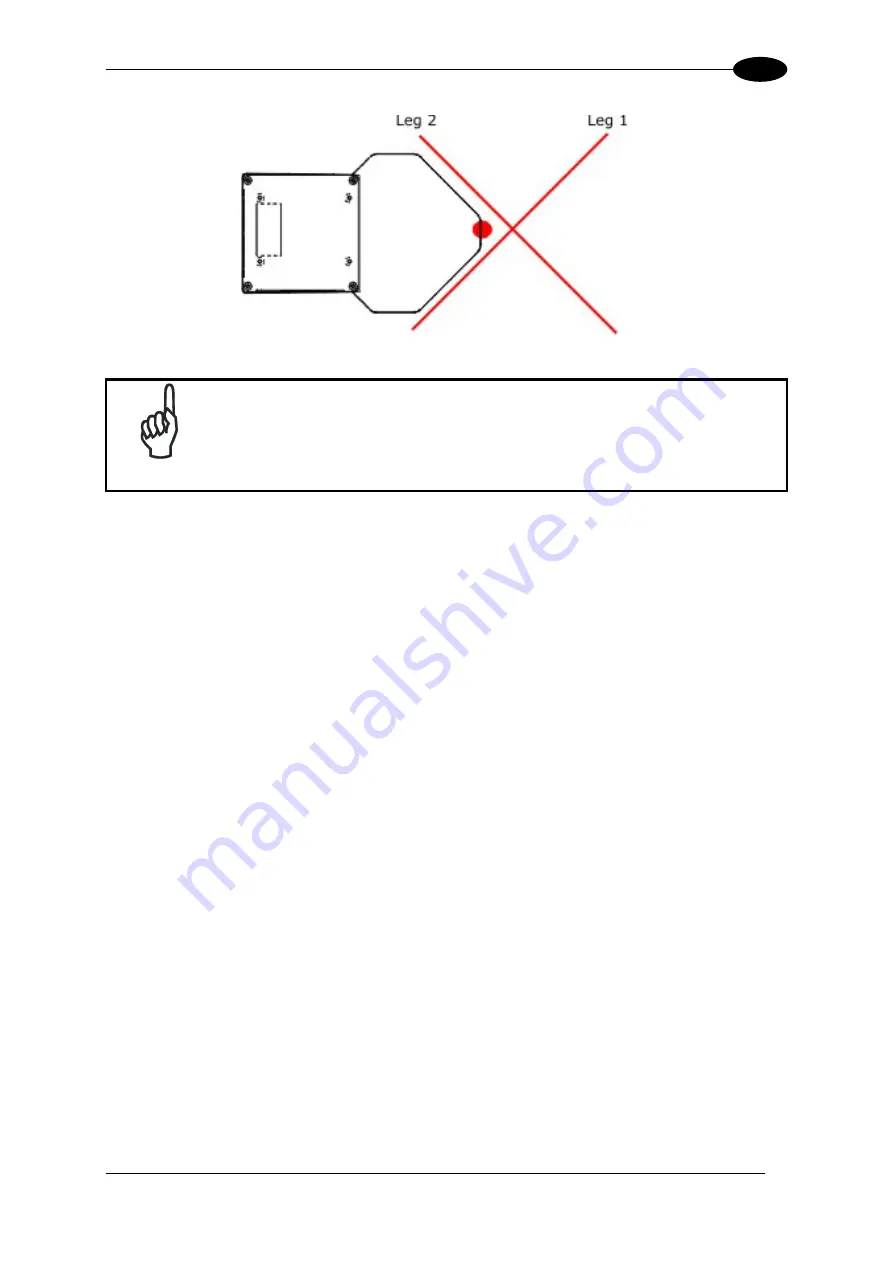

Figure 72 – DX6400 Scan Legs

NOTE

In the vast majority of systems the x and z data are not necessary. For

these cases set x = 0, z= 0 during the calibration procedure.

4.3 PERFORMANCE

The standard scan rate is 1200 scans/sec (600 scans on each leg).

Refer to the diagrams in par. 4.5 for further details on the reading features. These diagrams

are taken on various resolution sample codes at a 25

°

C ambient temperature depending on

the conditions listed under each diagram.

If standard models do not satisfy specific requirements, contact your nearest Datalogic

distributor, supplying code samples, to obtain complete information on the reading

possibilities.

63

Summary of Contents for DX6400

Page 1: ...DX6400 Reference Manual ...

Page 94: ...www automation datalogic com ...