DX8200

24

2

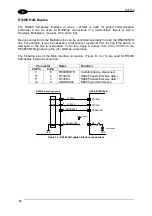

2.4.6 Outputs

The relative signals are available on the

Output Signal connector

(Figure B, 3) and on the

25-pin I/O connector

(Figure B, 5).

Connector

Name

Function

25-pin

9-Pin

13

1

VS

power for external devices (positive pin)

1

2

GND

power for external devices (negative pin)

11

3

NO READ+

no read

3

4

NO READ-

no read output -

23

5

RIGHT+

right code

16

6

RIGHT-

right code output -

7

SPS+

slave presence

8

SPS-

slave presence sensor -

A 24 Vdc output voltage, is present between VS and GND. This may be used to power external

devices: electrical isolation between the scanner and external devices is lost in this case.

The

No Read

output activates when a code signaled by the presence sensor is not decoded.

The

Right

output is used to signal the presence of a right code, thus a good decode

condition.

All outputs are level or pulse programmable: a 50 ms pulse is generated in the second case.

Further programming information is supplied in the WinHost Help File.

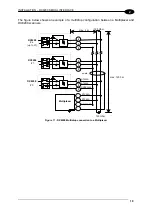

These outputs are created using optoisolated Darlington drivers and supply both the collector

and emitter in output, allowing both loads referenced to ground and to the power supply to be

driven.

The electrical features are given below:

Collector-emitter voltage

30 V Max.

Collector current

130 mA Max (pulsed).

Saturation voltage (VCE)

1 V at 10 mA Max.

Maximum power dissipation

90 mW at 50 °C (Ambient temperature).

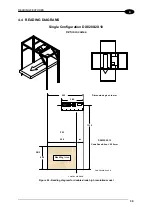

DX8200 9-pin Connector

USER INTERFACE

NO READ+

RIGHT+

Vext

30 Vdc max

NO READ-

RIGHT-

3/5

4/6

Figure 28 - Output interface

When the load is powered by an external power supply, the voltage must be less than 30 V.

The limit requested by the maximum power dissipation is more important than that of the

maximum collector current: if one of these outputs is continuously driven, the maximum

current must not be more than 40 mA although 130 mA may be reached in pulse conditions.