PackTrack™

Reference Manual

225

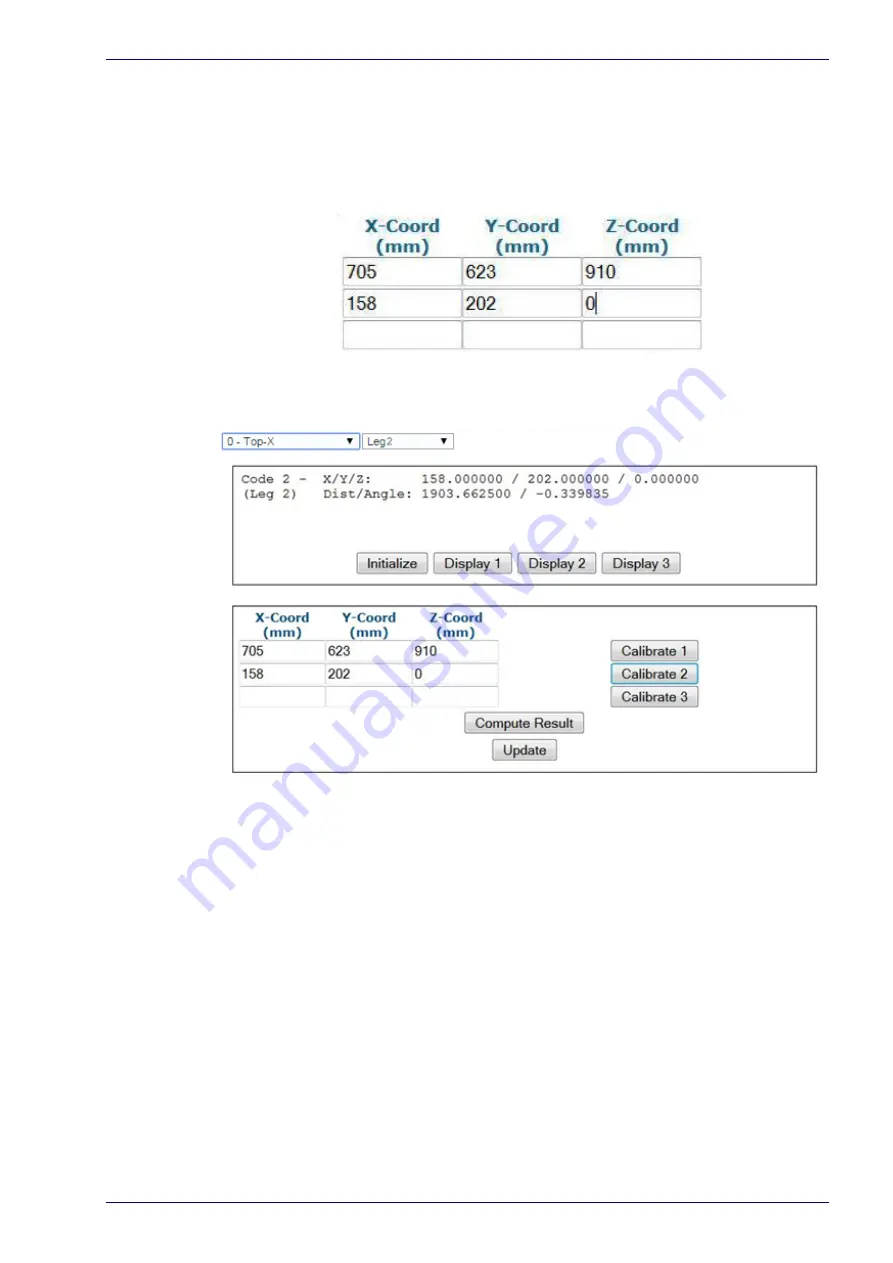

28.Measure the distance for Z from the conveyor bed to the barcode, and enter

that distance in the first box under

Z-Coord (mm)

. Since the barcode is

directly on the conveyor bed, the value should be "0."

Your measurements will likely differ from those shown below.

29.Click Calibrate 2. PackTrack data is displayed for the first code.

30.Next, place a system barcode on the conveyor bed in the laser line close to

the right edge of the conveyor bed.

See illustration below.

Summary of Contents for DX8210

Page 1: ...DX8210 Reference Manual Omnidirectional Barcode Scanner ...

Page 31: ...Installation Reference Manual 19 Small Side Mounted L Bracket Options ...

Page 45: ...Tachometer Wiring to CBX510 Reference Manual 33 ...

Page 47: ...Tachometer Wiring to CBX510 Reference Manual 35 ...

Page 49: ...Digital Output Configuration to CBX510 Reference Manual 37 Unpowered Outputs Powered Outputs ...

Page 268: ...Barcode Scanning Features 256 DX8210 Barcode Scanner DX8210 2100 0 25 mm 10mil ...

Page 269: ...Reading Diagrams Reference Manual 257 DX8210 2100 0 30 mm 12mil ...

Page 270: ...Barcode Scanning Features 258 DX8210 Barcode Scanner DX8210 2100 0 38 mm 15mil ...

Page 271: ...Reading Diagrams Reference Manual 259 DX8210 2100 0 50 mm 20 mil ...

Page 272: ...Barcode Scanning Features 260 DX8210 Barcode Scanner DX8210 4100 0 38 mm 15 mil ...

Page 273: ...Reading Diagrams Reference Manual 261 DX8210 4100 0 50 mm 20 mil ...

Page 274: ...Barcode Scanning Features 262 DX8210 Barcode Scanner DX8210 4200 0 25 mm 10 mil ...

Page 275: ...Reading Diagrams Reference Manual 263 DX8210 4200 0 30 mm 12 mil ...

Page 297: ...Reference Manual 285 ...

Page 298: ......

Page 299: ......