Ventilation and Spacing

Technical Guide

2-7

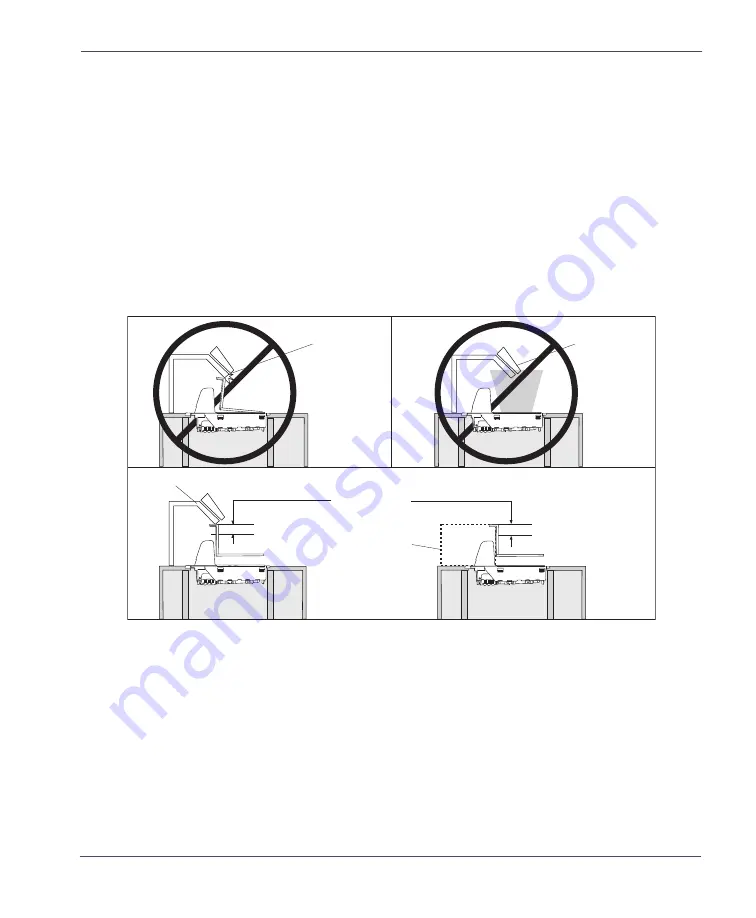

Vertical Clearance —

Provision must be made to allow adequate space

above the scanner bonnet for removal and replacement of an L-shaped

platter. Optimal clearance permits the platter to be grasped at its top verti-

cal edge and lifted for removal without obstruction (such as a fixed key-

board mount or any type of enclosure). Should such an enclosure be

unavoidable, an alternate method of platter removal using two coins may

be employed, however a minimum vertical clearance of 1.5” (3.8 cm)

MUST be provided (reference

Figure 2-4

). Another consideration is that

the scan zone must be kept free of obstructions such as enclosures, key-

board mounts, etc.

Figure 2-4. Vertical Clearance

Ventilation and Spacing

The scanner/scale’s perimeter housing has been designed to provide ade-

quate space for convective cooling and unrestricted movement of the

weighing apparatus.

Figure 2-5

shows the debris chutes and ventilation

slots. The checkstand design must allow:

•

The ambient air temperature inside the checkstand adjacent to the

scanner must not exceed 104°F (40°C).

DO NOT

Ob

s

tr

u

ct

S

c

a

n Zone

DO NOT

Ob

s

tr

u

ct

L-Pl

a

tter

Remov

a

l

Allow

a

minim

u

m

cle

a

r

a

nce of

1.5" (

3

.

8

cm)

(Enclo

su

re)

(Keybo

a

rd Mo

u

nt)

Summary of Contents for MAGELLAN 8300

Page 1: ...MagellanTM 8300 8400 Technical Guide...

Page 3: ...Product Reference Guide 3...

Page 4: ......

Page 16: ...1 10 Magellan 8300 8400 NOTES...

Page 64: ...4 12 Magellan 8300 8400 NOTES...

Page 83: ...Interface Related Features Technical Guide 5 19 NOTES...

Page 84: ...5 20 Magellan 8300 8400 NOTES...