Product Reference Guide

2-7

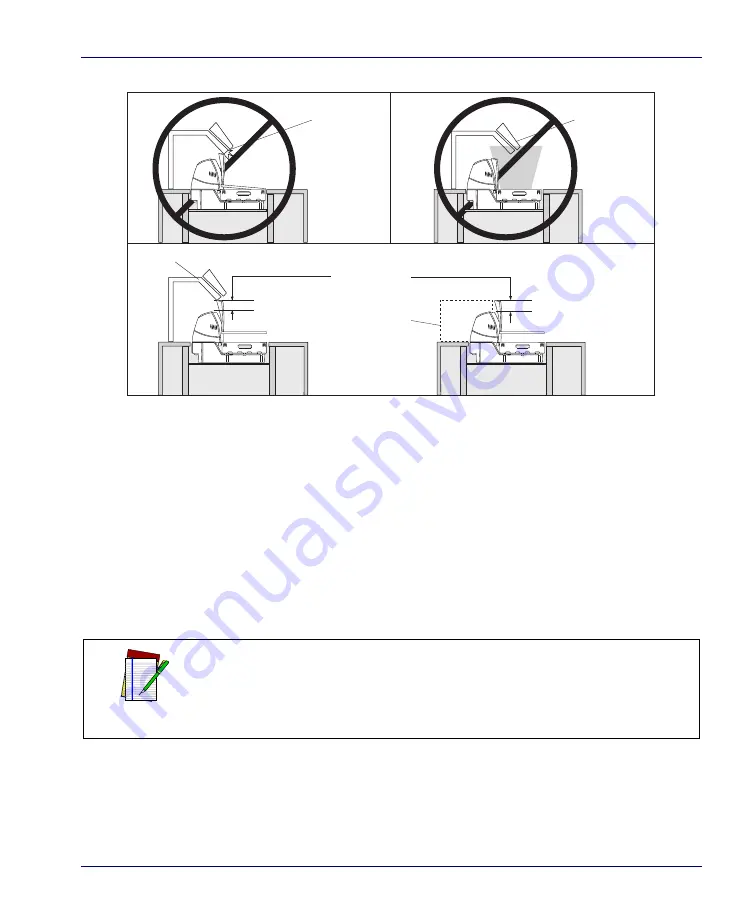

Figure 2-2. Vertical Clearance

Ventilation and Spacing

The scanning-scale’s perimeter housing has been designed to provide ade-

quate space for convective cooling and unrestricted movement of the

weighing apparatus.

shows the debris chutes and ventilation

slots. The checkstand design must allow:

•

The ambient air temperature inside the checkstand adjacent to

the scanner must not exceed 104°F (40°C).

•

A source of air that provides adequate cooling by convective air

flow.

If motors, conveyor belts, or other heat producing equipment are located

near the scanner, forced air ventilation may be required. In most installa-

tions, a 30 cfm (.84 cmm) axial fan should provide sufficient air move-

ment. If a ventilation fan is installed, one with a removable filter that may

be washed or replaced is recommended.

DO NOT

Obstruct

Scan Zone

DO NOT

Obstruct

L-Platter

Removal

Allow a minimum

clearance of

1.5" (3.

8

cm)

(Enclosure)

(Keyboard Mount)

NOTE

DO NOT place the scanner in a close-fitting, fully enclosed checkstand. Pro-

vide a MINIMUM of 16 square inches (103.2 square centimeters) of air intake

from below the installation for sufficient convective cooling.

Summary of Contents for MAGELLAN 8500?

Page 1: ...Magellan 8500 Product Reference Guide...

Page 14: ...12 Magellan 8500 Scanner NOTES...

Page 66: ...2 36 Magellan 8500 Scanner NOTES...

Page 84: ...3 18 Magellan 8500 Scanner Figure 3 6 Removing Replacing the Gasketed DLC Window a b c d...

Page 89: ...Product Reference Guide 4 5 Figure 4 1 7 Segment LED Display 7 Segment Display Models vary...

Page 98: ...4 14 Magellan 8500 Scanner NOTES...

Page 420: ...D 2 Magellan 8500 Scanner NOTES...

Page 436: ...E 16 Magellan 8500 Scanner NOTES...

Page 452: ...F 16 Magellan 8500 Scanner NOTES...

Page 453: ...Product Reference Guide F 17 NOTES...

Page 454: ...F 18 Magellan 8500 Scanner NOTES...