MATRIX 450™ QUICK REFERENCE GUIDE

31

COMPLIANCE

See the Matrix 450™ Reference Manual for the Declaration of Conformity.

Only connect Ethernet and dataport connections to a network which has routing only within the plant

or building and no routing outside the plant or building.

EMC COMPLIANCE

In order to meet the EMC requirements:

connect reader chassis to the plant earth ground by means of a flat copper braid shorter than

100 mm;

connect pin "Earth" of the CBX connection box to a good Earth Ground;

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This product is intended to be connected to a UL Listed Computer which supplies power directly to the

reader or a UL Listed Direct Plug-in Power Unit marked LPS or “Class 2”.

CE COMPLIANCE

Warning:

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of Datalogic could

void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

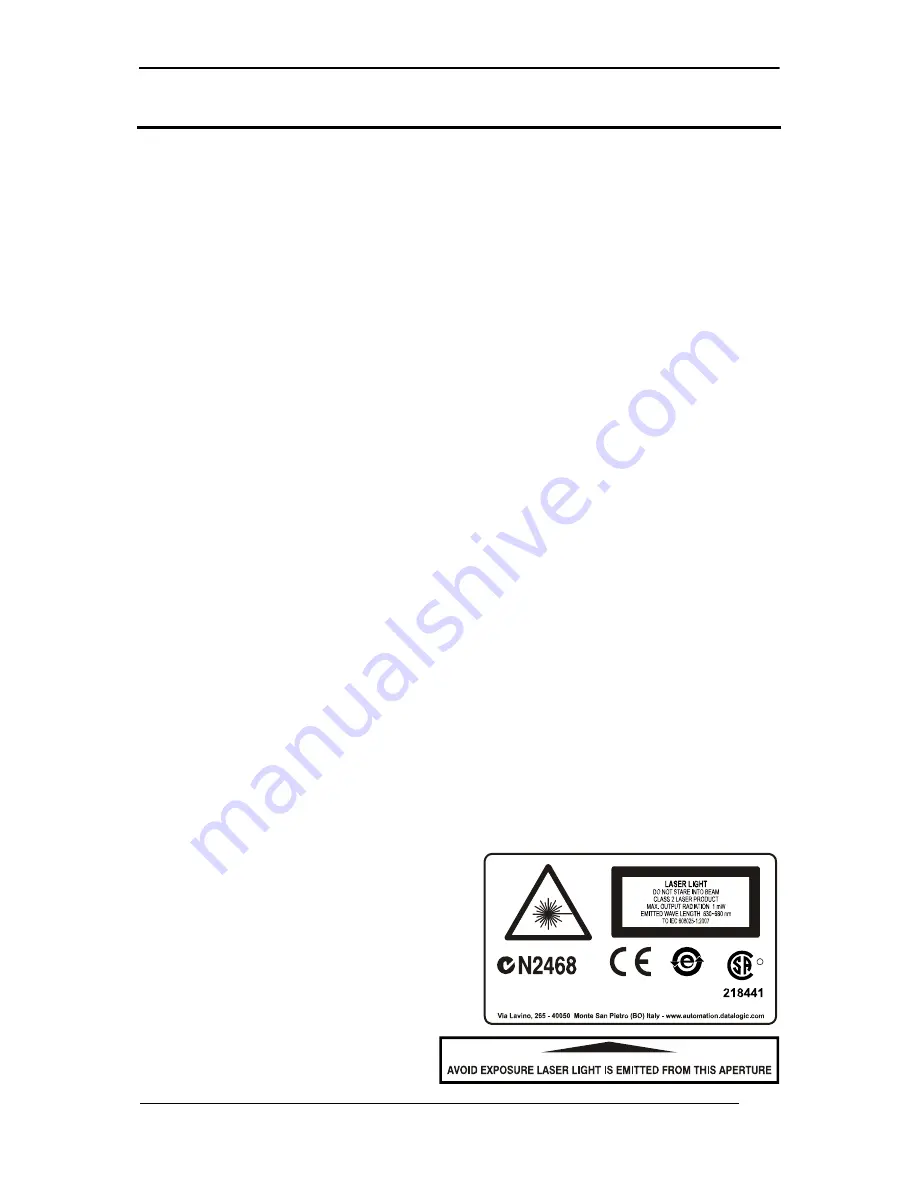

LT-03X LASER SAFETY

The LT-03x Series Lighting Systems contain two

aiming Laser LEDs used to position the reader.

Therefore the product is classified as a Class 2 laser

product according to IEC 60825-1 regulations and

as a Class II laser product according to CDRH

regulations. Disconnect the power supply when

opening the device during maintenance or

installation to avoid exposure to hazardous laser

light. The laser beam can be switched on or

off through a software command.

C

R

US

This product is covered by one or more of following patents:

U.S. Pat.: 6,808,114 B1; 6,997,385 B2; 7,387,246 B2.

See product manual and package for entire patent listing.

DATALOGIC AUTOMATION S.r.l.