VLASE

TM

IR

12

1

1.4 TRANSPORT

The marking system needs to be moved in order to proceed to its positioning and wiring. The marking

system can

’t be lifted up and moved by a single person.

WARNING!

To avoid damaging or breaking the optical fiber, never subject it to a bending radius below the limits

specified in the technical specification table.

Figure 3: Transport.

WARNING!

Vlase

TM

is a delicate optical laser marking system, avoid damaging it with shock and vibrations.

WARNING!

Be extremely careful to not damage the fiber optic cable between resonator and rack.

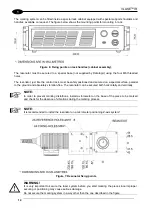

1.5 ON MOISTURE CONDENSATION

If the marking system is brought directly from a cold to a warm location, moisture may condense inside or

outside the marking system. This moisture condensation may cause a malfunction of the marking system.

If moisture condensation occurs

Turn off the marking system and wait about 1 hour for the moisture to evaporate.

Note on moisture condensation

Moisture may condense when you bring the marking system from a cold place into a warm place (or vice

versa) or when you use the marking system in a humid place.

How to avoid moisture condensation

When you bring the marking system from a cold place into a warm place, put it in a plastic bag and seal it

tightly. Remove the bag when the air temperature inside the plastic bag has reached the ambient

temperature (after about 1 hour).

Summary of Contents for VLASE IR 1PWX-TLS2

Page 1: ...USER S MANUAL VLASETM IR ...

Page 34: ...VLASETM IR 34 2 2 6 CONNECTION EXAMPLES Figure 27 Connection examples ...

Page 85: ...85 EXTERNAL LABEL PLACING Figure 67 Positioning of external labels rack ...

Page 86: ...86 Figure 68 Positioning of external labels resonator ...

Page 90: ...90 BLOCK DIAGRAM VLASETM SAFETY LOGIC DETAILS FOR AUTOMATIC PRODUCTION LINE ...

Page 108: ...108 APPENDIX G MECHANICAL DRAWINGS ...

Page 109: ...109 NOTE Please refer to Datalogic website for detailed drawings ...

Page 112: ......