VLASE

TM

IR

14

1

The marking system can be fitted inside a special rack cabinet equipped with special support shoulders and

handles, available on request. The figure below shows the mounting points for mounting in rack:

Figure 6: Fixing points on rack handles (cabinet assembly).

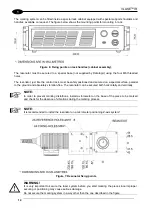

The resonator must be secured to a special base (not supplied by Datalogic) using the four M6 threaded

holes.

The resonator, just like the control rack, must be safely positioned and secured on a special surface, parallel

to the ground and absolutely vibration-free. The resonator can be secured both horizontally and vertically.

NOTE:

In order to prevent marking distortions, install a vibrometer on the base of the piece to be marked

and check for the absence of vibrations during the marking process.

NOTE:

It is recommended to install the resonator on a micrometer positioning Z-axis system!

Figure 7: Resonator fixing points

WARNING!

It is very important to secure the laser system before you start marking the piece since improper

securing or positioning may cause serious damage.

Do not secure the marking system in a way other than the one described in the figure.

Summary of Contents for VLASE IR 1PWX-TLS2

Page 1: ...USER S MANUAL VLASETM IR ...

Page 34: ...VLASETM IR 34 2 2 6 CONNECTION EXAMPLES Figure 27 Connection examples ...

Page 85: ...85 EXTERNAL LABEL PLACING Figure 67 Positioning of external labels rack ...

Page 86: ...86 Figure 68 Positioning of external labels resonator ...

Page 90: ...90 BLOCK DIAGRAM VLASETM SAFETY LOGIC DETAILS FOR AUTOMATIC PRODUCTION LINE ...

Page 108: ...108 APPENDIX G MECHANICAL DRAWINGS ...

Page 109: ...109 NOTE Please refer to Datalogic website for detailed drawings ...

Page 112: ......