CONTENTS OF THE PACKING

15

1

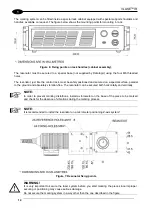

1.7 INSTALLATION ENVIRONMENT

The control rack must be installed in a suitable environment in order to allow proper air flow passage and

correct housing of the cables.

Vlase

TM

is an air cooled marking system: an adequate air flow is necessary to guarantee correct cooling of

the system. Install the rack so that air flow is not obstructed. Moreover, do not install it near a heat source.

Clean the air filter when it is dirty. If the air filter is dirty, insufficient air-flow might not ensure correct cooling

and might stop the marking operation. Clean or replace the air filter periodically.

Figure 8: Rack installation environment.

WARNING!

DO NOT

place heavy objects on top of the rack!

In order to have the marking system operating in safety mode (see Appendices for more details) we

recommend installing the marking system as shown in the figure below in order to limit the laser output area.

To obtain a good marking quality, and to avoid decreasing system life time, we recommend a ventilation or

vacuum system in a protection box to limit dust due to the marking phase.

Figure 9: Safety mode example.

Summary of Contents for VLASE IR 1PWX-TLS2

Page 1: ...USER S MANUAL VLASETM IR ...

Page 34: ...VLASETM IR 34 2 2 6 CONNECTION EXAMPLES Figure 27 Connection examples ...

Page 85: ...85 EXTERNAL LABEL PLACING Figure 67 Positioning of external labels rack ...

Page 86: ...86 Figure 68 Positioning of external labels resonator ...

Page 90: ...90 BLOCK DIAGRAM VLASETM SAFETY LOGIC DETAILS FOR AUTOMATIC PRODUCTION LINE ...

Page 108: ...108 APPENDIX G MECHANICAL DRAWINGS ...

Page 109: ...109 NOTE Please refer to Datalogic website for detailed drawings ...

Page 112: ......