TECHNICAL SPECIFICATIONS

25

2

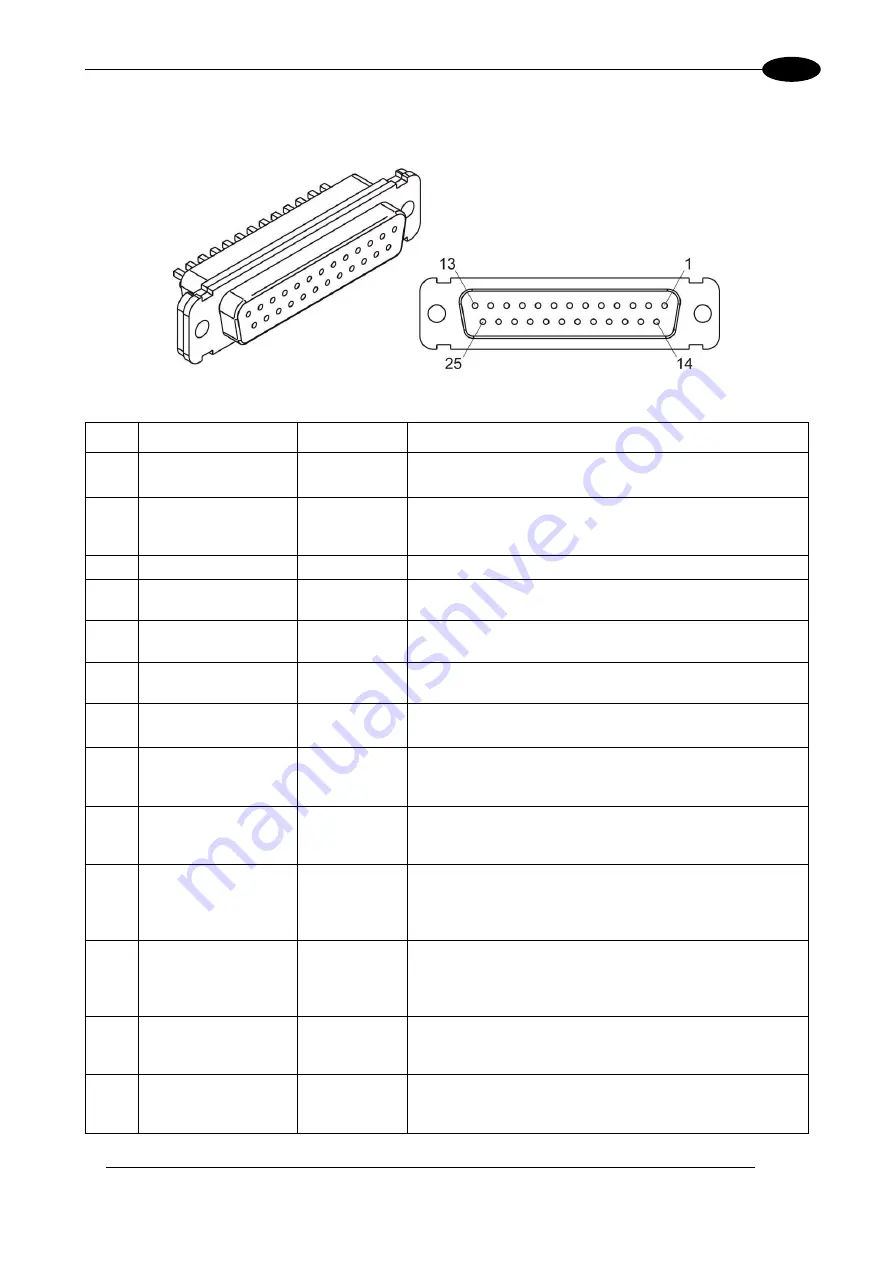

2.4.3 COMMAND BOX CONNECTOR (LASER CONTROL)

Panel socket Sub-D, 25 pins, female.

Figure 18: Female panel socket Sub-D 25 (front view).

PIN SIGNAL

TYPE

(***)

DESCRIPTION

1

12V_ENABLE_B

Output power

supply

12V DC power supply available for

EXT_ENABLE_B

(max 250mA)

2

EXT_ENABLE_B

Digital Input

Secondary external

ENABLE

signal (see par. 2.4.3.1)

- HIGH level: contact closed

- LOW level or disconnected: contact opened

3

RESERVED

Digital Output

DO NOT CONNECT

4

EXT_12V

Output power

supply

Auxiliary 12V DC power supply available for drive input

logical HIGH (max 250mA)

5

EXT_12V

Output power

supply

Auxiliary 12V DC power supply available for drive input

logical HIGH (max 250mA)

6

EXT_12V

Output power

supply

Auxiliary 12V DC power supply available for drive input

logical HIGH (max 250mA)

7

12V_ENABLE_A

Output power

supply

12V DC power supply available for

EXT_ENABLE_A

(max 250mA)

8

EXT_ENABLE_A

Digital Input

Primary external

ENABLE

signal (see par. 2.4.3.1):

- HIGH level: contact closed;

- LOW level or disconnected: contact opened

9

BUSY (*)

Digital Output

This signal is used to know if the current spooler is

executing (marking in progress) (see par. 2.4.3.4):

- ON during marking process

10

CONNECTOR

PRESENCE

Digital Input

This signal is used to check the presence of the

Command Box connector (see paragraph 2.6):

- HIGH level: normal operation;

- LOW level or disconnected: laser source faulty

11

START MARKING

(*)

Digital Input

This signal is used to start to the marking process when a

document or a sequence is running in AUTO MODE (**)

or WORK MODE (**) (see paragraph 2.4.3.4):

- HIGH level pulsed signal start the marking process

12

EXT_KEY

Digital Input

External

KEY

signal (see paragraph 2.4.3.2):

- HIGH level: contact closed;

- LOW level or disconnected: contact opened

13

STOP MARKING (*)

Digital Input

This signal is used to stop the marking process (see

paragraph 2.4.3.4)

- HIGH level pulsed signal stop the marking process

Summary of Contents for VLASE IR 1PWX-TLS2

Page 1: ...USER S MANUAL VLASETM IR ...

Page 34: ...VLASETM IR 34 2 2 6 CONNECTION EXAMPLES Figure 27 Connection examples ...

Page 85: ...85 EXTERNAL LABEL PLACING Figure 67 Positioning of external labels rack ...

Page 86: ...86 Figure 68 Positioning of external labels resonator ...

Page 90: ...90 BLOCK DIAGRAM VLASETM SAFETY LOGIC DETAILS FOR AUTOMATIC PRODUCTION LINE ...

Page 108: ...108 APPENDIX G MECHANICAL DRAWINGS ...

Page 109: ...109 NOTE Please refer to Datalogic website for detailed drawings ...

Page 112: ......