Appendix J – General Purpose Input Output Port Applications

268

Class Series 2 Programmer’s Manual

M-Class II GPIO

MII GPIO functions are detailed in the table below:

MII GPIO Overview

Pin

Number

Signal

Name

Signal

State

Signal

Direction*

Description

1

Vcc

+5 VDC

Output

Printer: Max +5 VDC, 100mA

2

Printer

Fault

Low

Output

Goes low upon printer detection of a fault

condition. Max +5 VDC, 100mA

3

Spare

Reserved

Input

Must be pulled high with 1k Ohm resistor

(see sample SOP circuit, below).

4

Start of

(SOP)

Programmable

Input

When active, will begin print. Recommend

only setting this signal to ACTIVE LOW.

When ready to print a label, the applicator

should hold this signal low for at least 50ms

– or until EOP goes not active. See sample

SOP circuit, below. Max +3.27 VDC, +/-

5mA

5

End of

(EOP)

Programmable

Output

Signifies the end of the print process. Can

be monitored to initiate next Start of Print

sequence. Minimum signal time 30ms. Max

+5 VDC, 100mA

6 & 8

Signal

Ground

Ground

N/A

Ground

7

+24 VDC

500mA

Output

Printer: Max +24 VDC, 500mA

[1]

Given relative to the printer.

[2]

Port operation is configuration dependent: Disable all unused optional functions (e.g., Present Sensor

or Cutter) and set GPIO to “YES” (or on display-equipped models, to APPLICATOR). Use the

Configuration Set command (

<STX>Kc

); or program the selections for non-display models via the

“Printer Setup Menu List” and for display-equipped models via the menu.

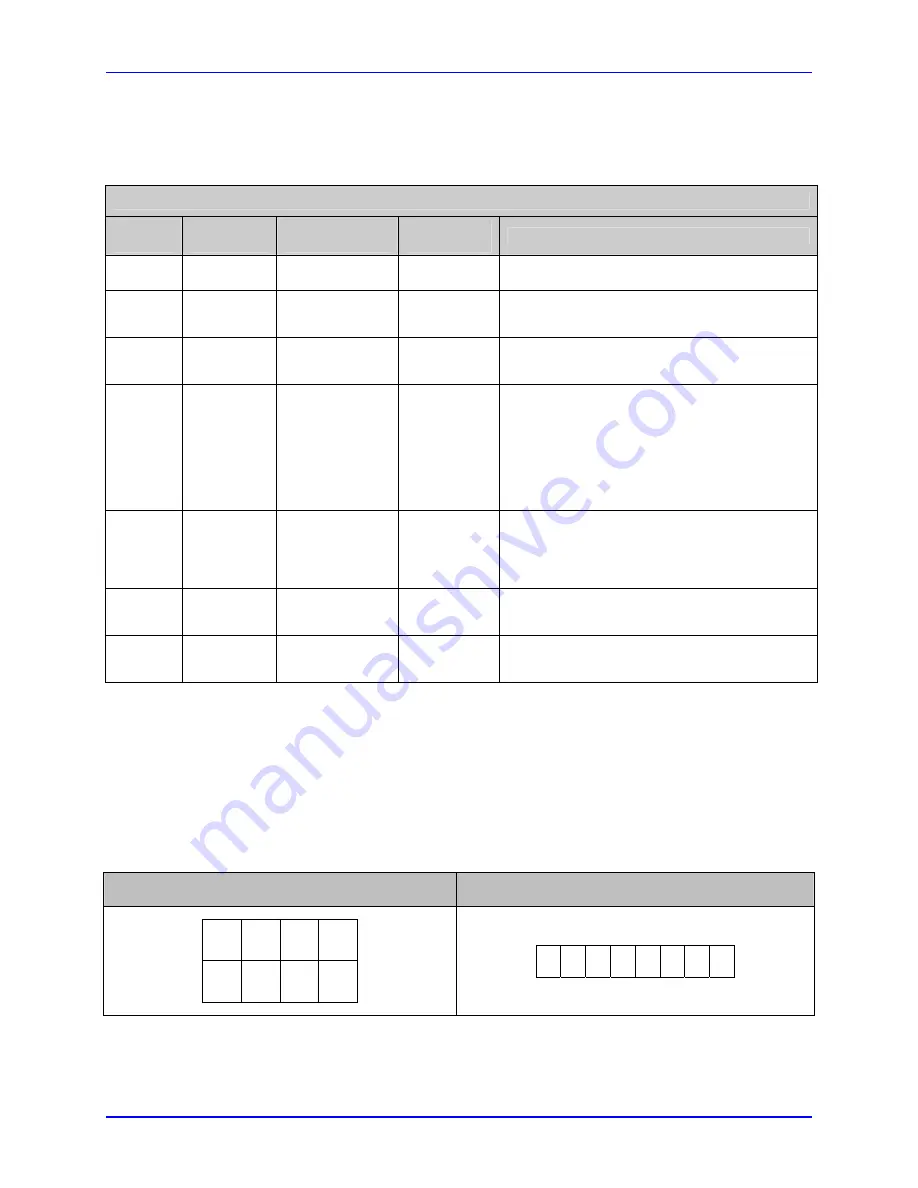

The GPIO signals can be accessed via the front Option Port connector (Molex, P/N 44300-

800), or via the Main PCB J6 connector (AMP, P/N 640456-8), where the pin-outs (as

viewed when facing the printer) are as follows:

Option Port

Main PCB (J6)

8 6 4 2

7 5 3 1

1 2 3 4 5 6 7 8

Summary of Contents for A-Class

Page 2: ......

Page 3: ......

Page 5: ......

Page 6: ......

Page 22: ...Overview 8 Class Series 2 Programmer s Manual ...

Page 30: ...Immediate Command Functions 16 Class Series 2 Programmer s Manual ...

Page 138: ...Extended System Level Command Functions 124 Class Series 2 Programmer s Manual ...

Page 160: ...Label Formatting Command Functions 146 Class Series 2 Programmer s Manual ...

Page 180: ...Generating Label Formats 166 Class Series 2 Programmer s Manual ...

Page 192: ...Appendix B Sample Programs 178 Class Series 2 Programmer s Manual ...

Page 200: ...Appendix D Reset Codes 186 Class Series 2 Programmer s Manual ...

Page 212: ...Appendix E Single Byte Symbol Sets 198 Class Series 2 Programmer s Manual ...

Page 264: ...Appendix G Bar Code Details 250 Class Series 2 Programmer s Manual ...

Page 308: ...Appendix Q Plug and Play IDs 294 Class Series 2 Programmer s Manual ...

Page 312: ...Appendix R Line Mode 298 Class Series 2 Programmer s Manual ...

Page 324: ...Appendix T WiFi Region Country Codes 310 Class Series 2 Programmer s Manual ...

Page 334: ......