94

A-Class

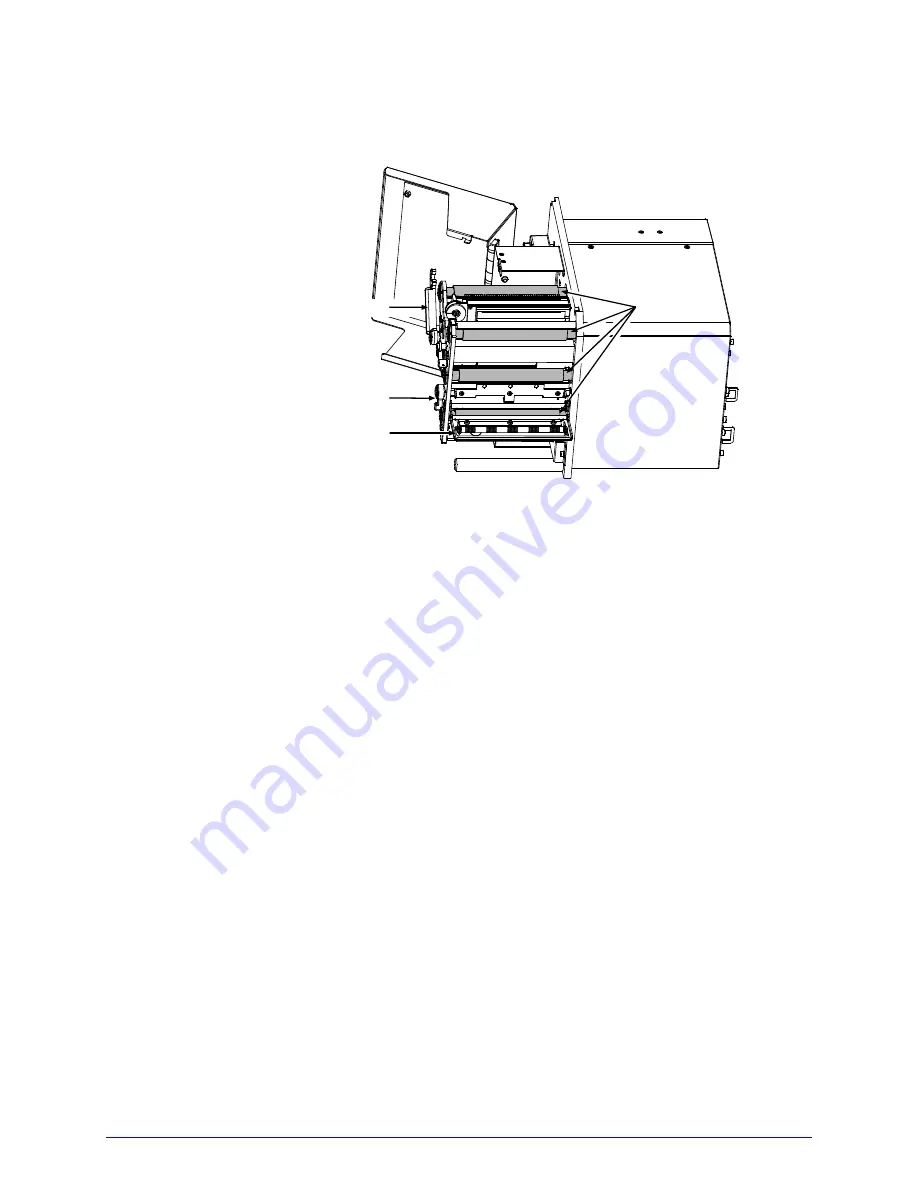

2. Raise the Head Lift Lever. Lower the Peel Assembly Release Lever. Remove media and

ribbon.

Rollers

Peel Assembly

Peel Assembly Release Lever

Head Lift Lever

3. Using a cotton swab dampened with isopropyl alcohol, clean the Rollers, rotating each as

necessary to clean its entire surface.

4. After allowing the Rollers to dry, replace ribbon and media. Close the Peel Assembly and

lower the Head Lift Lever into the locked position.

5. Close the access cover. Plug in and turn ON the printer. This completes the procedure.

5.5.3 Cleaning the Peel Assembly

Clean the Peel Assembly as follows:

1. Turn OFF and unplug the printer. Raise the access cover.

2. Raise the Head Lift Lever. Lower the Peel Assembly Release Lever. Remove media and

ribbon.

Summary of Contents for A-Class A-4212

Page 1: ...Operator s Manual ...

Page 2: ......

Page 5: ......

Page 6: ......

Page 8: ......

Page 14: ...vi ...

Page 22: ...8 A Class ...

Page 84: ...70 A Class ...

Page 128: ...114 A Class ...

Page 136: ...122 A Class ...

Page 140: ...126 A Class ...

Page 144: ...130 A Class ...

Page 158: ...144 A Class ...

Page 160: ...146 A Class ...

Page 166: ...152 A Class ...