88

A-Class

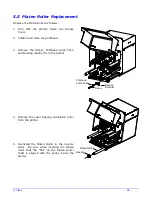

4. Raise the Head Lift Lever then gently slide the Printhead forward. Carefully disconnect both

Printhead Cables, and then remove the Printhead.

5. While carefully protecting the

new

Printhead, connect both Printhead Cables.

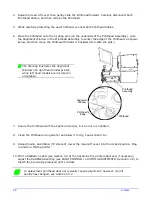

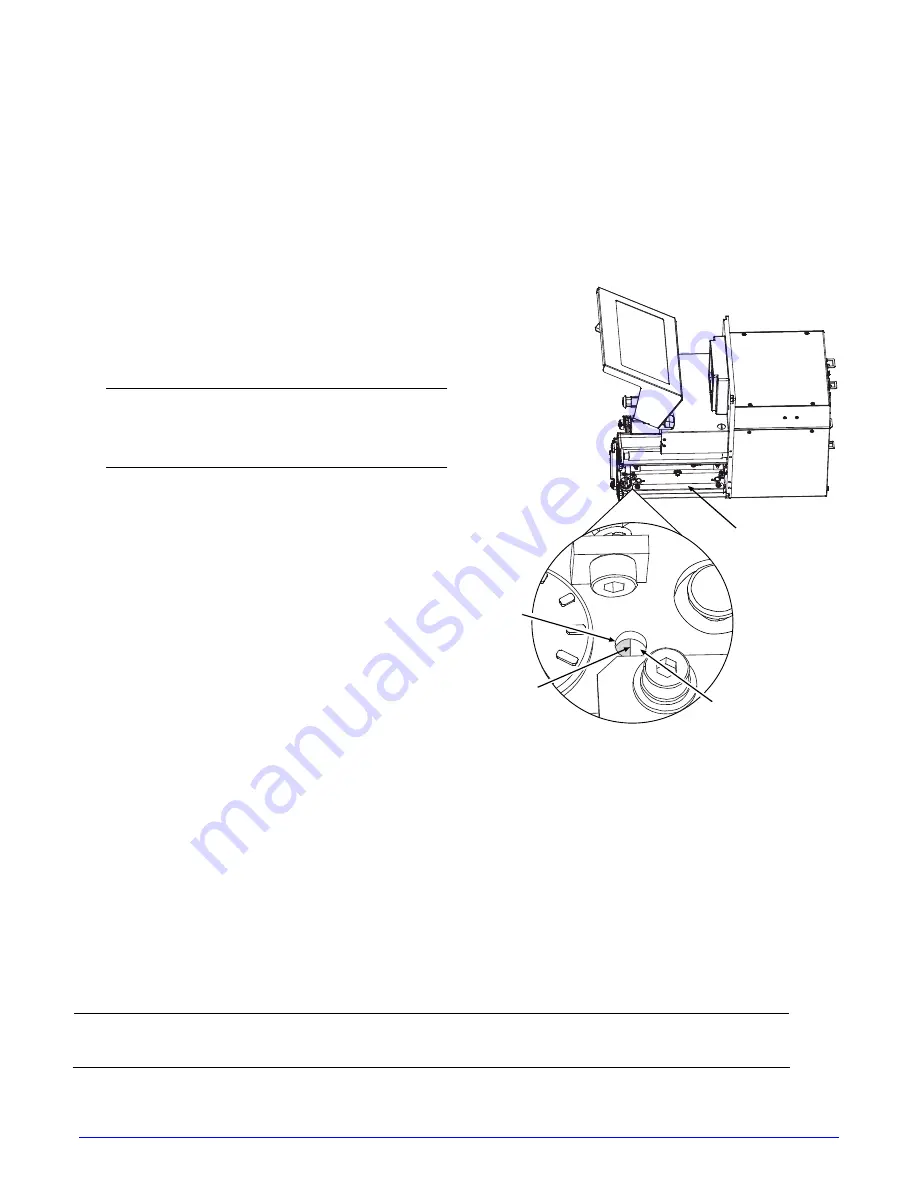

6. Place the Printhead onto the locating pins (on the underside of the Printhead Assembly). (Use

the Alignment Window in the Printhead Assembly to center the edge of the Printhead, as shown

below, and then move the Printhead forward or backward to locate the pins.)

The drawing illustrates the Alignment

Window of a right hand model printer,

while left hand models are mirrored in

orientation.

Printhead’s

Edge

Printhead

Assembly

Printhead

Alignment

Window

7. Secure the Printhead with the Captive Screw(s), but do not over-tighten.

8. Clean the Printhead using alcohol and allow it to dry; see Section 5.6.1.

9. Reload media, and ribbon (if removed), lower the Head Lift Lever into the locked position. Plug

in and turn ON the printer.

10. Print a Validation Label (see Section 4.3.4) then examine the printed label and, if necessary,

adjust the DARKNESS setting (see PRINT CONTROL / CUSTOM ADJUSTMENTS, Section 4.2.2) to

match the previously produced print contrast.

A replacement printhead does not typically require alignment; however, if print

quality has changed, see Section 5.3.2.

Summary of Contents for A-Class Mark II

Page 1: ...Operator s Manual ...

Page 2: ......

Page 5: ......

Page 20: ...10 A Class Peel Point Dimension See Appendix C for the PE Series printer s dimension Peel Bar ...

Page 80: ...70 A Class ...

Page 113: ...A Class 103 ...

Page 115: ...A Class 105 ...

Page 126: ...116 A Class ...

Page 134: ...124 A Class ...

Page 138: ...128 A Class ...

Page 142: ...132 A Class ...

Page 156: ...146 A Class ...

Page 158: ...148 A Class ...

Page 164: ...154 A Class ...