13

3.2.3 Dip Switch Functions

Note: Programmer’s refer to Developer Manual for more information

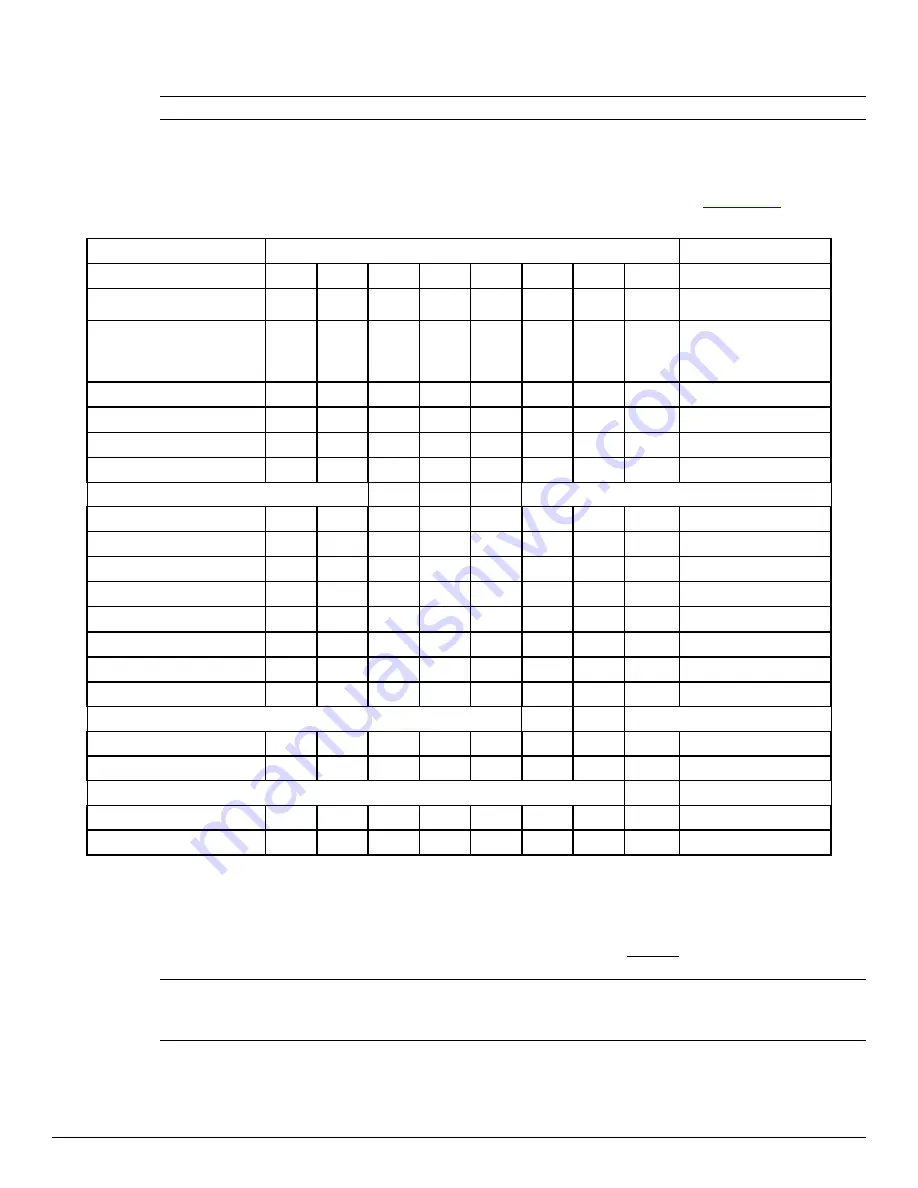

Table 3 – DIP Switch Setting

The APEX 4 printers support USB*

1

, Bluetooth™, Serial and Wi-Fi communication. Settings can

be changed via a DIP switch located on the battery compartment as shown in

Figure 10

.

Switch

#

Notes

Communication Interface

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

SW 7

SW 8

RS232

OFF

OFF

Baud rate set by Dip

switches 3,4 and 5

1

IrDA

ON

OFF

Baud Rate can be

negotiated up to the

value specified through

Dip switches 3,4 and 5

Bluetooth or 802.11g

OFF

ON

N/A

ON ON

Setting not supported

2

USB

X

X

OFF

OFF

ON

3

USB Bootloader

X

X

ON

OFF

ON

4

Baud Rate

SW 3

SW 4

SW 5

RS232 and IrDA only

115200

OFF

OFF

OFF

57600

ON

OFF

OFF

38400

OFF

ON

OFF

19200

ON ON

OFF

14400

OFF

OFF

ON

9600

ON

OFF

ON

Use for fixed IrDA

2400

OFF

ON ON

1200

ON ON ON

Parity Bit

SW 6

SW 7

Parity Enabled (ODD)

ON

ON

Does not apply for IrDA

Parity Enabled (EVEN)

ON

OFF

Does not apply for IrDA

Auto Power Save

SW 8

Power Save Enabled

ON

Auto Power Down

Power Save Disabled

OFF

Manual On/Off

1

If IrDA is not installed, printer will default to RS232 mode with baud rate 115200

2

X

stands for

Don’t Care

: Dip Switch 7 will override 1 and 2

3

Firmware Applies to Apex 4 - Version 1.10 or later.

4

Baud Rate and Parity are applicable to RS232 and IrDA communication mode

ONLY

Note: In order for changes to the dip switch configuration to take effect, the printer power must

be reset. This action occurs automatically when the battery is removed to gain access to

the dip switches.

Summary of Contents for Apex 4

Page 1: ...APEX 4 User Guide 7A300024 2 Rev A ...

Page 2: ......

Page 12: ...8 ...

Page 26: ...22 ...

Page 30: ......