88

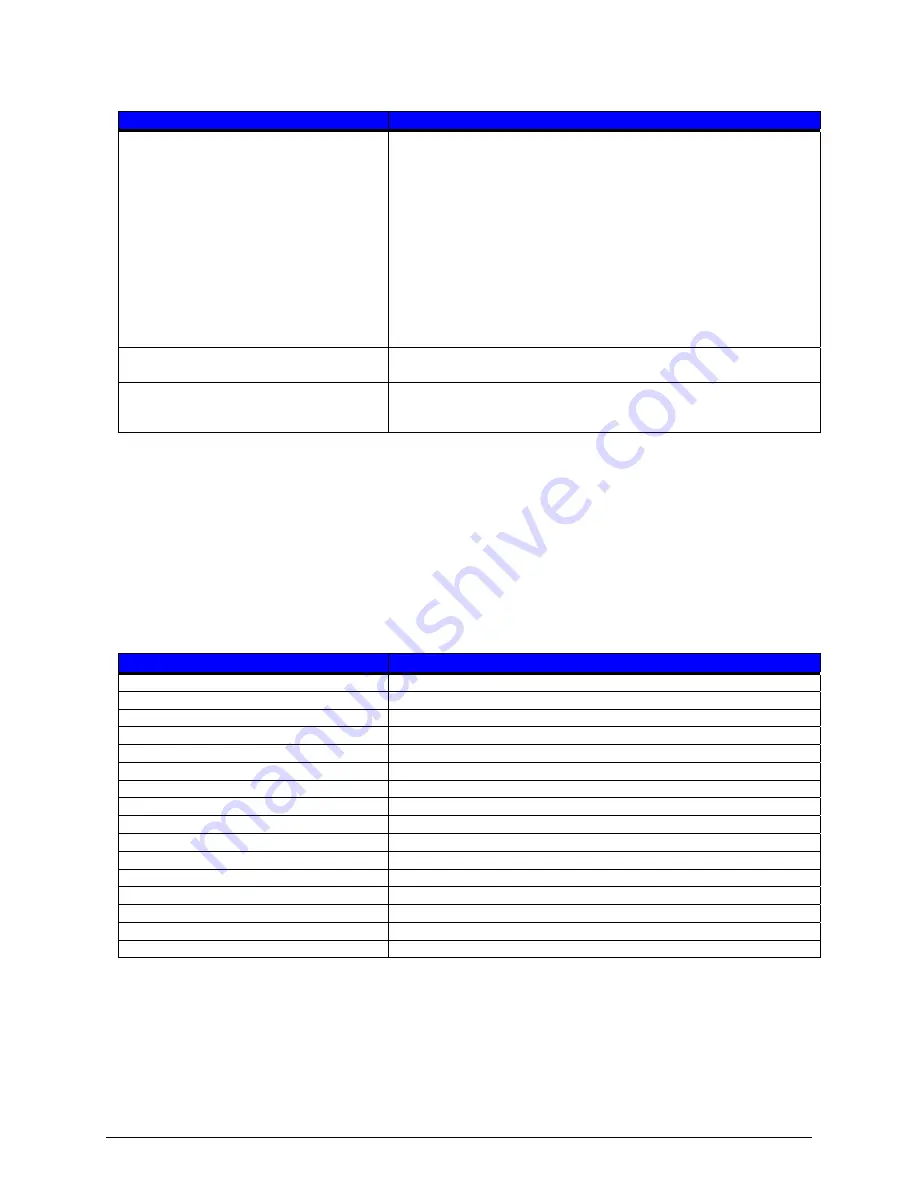

Symptom

Possible Solutions

Diminished print quality on the Quality

Label

Incomplete horizontal lines requires an increase in the sharpness

setting and/or more tension applied to the lighter print side of the

ribbon shield.

For higher-grade barcodes, lighten the print by reducing the darkness

setting.

For white specks inside dark boxes, increase the darkness setting

and clean the printhead and platen roller.

If the small font is not readable, increase the darkness setting.

When dithering increments are not equal, adjust the darkness setting.

If graphics are not displayed properly, adjust the sharpness setting.

Ladder barcode quality is diminished

Examine the media adjustment levers and ensure there is a

.8mm to 1.5mm gap between the levers and the media.

Image size is out of the print area (off the

side or top or truncated from the next

label

Turn off print truncation.

Ensure the image width is the same as the print width.

6.3. Error and Warning Messages

The printer displays messages when the possibility of a problem or an actual fault occurs.

Depending upon the displayed message, find the possible action or solution in the tables

below.

Error Messages

The following messages may be displayed:

Errors

Description

SYSTEM ERROR

Illegal label format or communications error

OUT OF RIBBON

Out of ribbon

OUT OF PAPER

Out of paper

CUTTER JAMMED

Cutter is jammed

REWINDER FULL

Rewinder is full

PRINTHEAD UNLATCHED

Printhead is unlatched

PRINTHEAD HOT

Printhead is critically hot

FPGA HARDWARE

Analog to digital converter hardware fault

NV RAM HARDWARE

Non-volatile memory hardware fault

PAPER SENSOR BLOCKED

Top-of-form sensor blocked or hardware fault

PAPER CALIBRATION

Could not calibrate media

NO TOP OF FORM FOUND

Could not find a gap or mark

RIBBON HARDWARE

Ribbon controller hardware fault

PRESENT SENSOR

Present Sensor hardware fault

GPIO HARDWARE

GPIO hardware fault

MOTOR HOT

Motor is critically hot

Note:

System errors are not caused by media mismatches but can be caused by a poor label

format.