Technical Manual

96

Operational Information

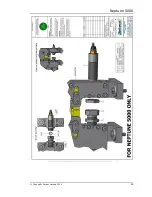

There are two very important criteria that must be observed when working

with the cone-up sensor.

1.

The magnetic flux unit and the sensor must be correctly orientated

to ensure correct operation. The two large spots on the magnetic

flux unit must be orientated vertically (in line with the cone-rod). On

the back of the sensor is a small location-marking slot. This must be

positioned in line with the magnetic flux unit’s black markers.

2.

The distance between the magnetic flux unit and the sensor is very

critical. It must be between approximately 30mm, symmetrically

positioned about the cone-rod.

Maintenance

NOTE:

Appropriate safe working practices should be followed to ensure that

all hazards are minimised.

When the system is in operation, the cone-up sensor should be washed down

with clean, salt-free water whenever it is returned to the deck of the ship. This

will reduce corrosion, and enable thorough inspection of all the main housings,

connector, and connecting cable.

It is good working practice to regularly check all fastenings to ensure they are

present, tight, and there is no damage to them or the items they are fitted to.

Any damaged fastenings should be replaced immediately.

The positioning and orientation of the sensors should be checked on a regular

basis. It is also necessary to ensure the lock nuts are tight.

The electrical cable connected to the cone-up sensor should be visually

inspected to ensure there are no chafes or cuts in the insulation. The

connectors on both ends of the cable should be tightly fitted with no face gap,

and the lock-rings should be finger-tight. Any damaged cables or lock-rings

should be replaced immediately.

Summary of Contents for Neptune 5000

Page 1: ...Neptune 5000 Copyright Datem Limited 2014 1 Neptune 5000 Technical Manual ...

Page 14: ...Technical Manual 14 Figure 3 Topside Control Box Wiring Schematic ...

Page 15: ...Neptune 5000 Copyright Datem Limited 2014 15 Figure 4 Topside Control Box Wiring Layout ...

Page 30: ...Technical Manual 30 ...

Page 32: ...Technical Manual 32 Figure 14 Transformer Pod General Arrangement ...

Page 36: ...Technical Manual 36 Figure 15 Transformer Pod Schematic ...

Page 39: ...Neptune 5000 Copyright Datem Limited 2014 39 Figure 16 Electronics Pod General Arrangement ...

Page 44: ...Technical Manual 44 Figure 19 Neptune 5000 Electronics Pod Wiring Schematic ...

Page 51: ...Neptune 5000 Copyright Datem Limited 2014 51 Figure 23 Inverter Pod General Arrangement ...

Page 52: ...Technical Manual 52 Figure 24 Inverter Pod Assembly ...

Page 55: ...Neptune 5000 Copyright Datem Limited 2014 55 Figure 25 Inverter Pod Wiring Schematic ...

Page 57: ...Neptune 5000 Copyright Datem Limited 2014 57 Figure 26 Inverter Function Settings ...

Page 62: ...Technical Manual 62 Figure 27 Thruster General Assembly ...

Page 63: ...Neptune 5000 Copyright Datem Limited 2014 63 Figure 28 Thruster Backplate and Driver Assembly ...

Page 64: ...Technical Manual 64 Figure 29 Thruster Drum and Cassette Assembly ...

Page 68: ...Technical Manual 68 ...

Page 70: ...Technical Manual 70 Figure 30 Thruster Straightener Assembly ...

Page 77: ...Neptune 5000 Copyright Datem Limited 2014 77 Figure 34 5cm2 Digital Cone Assembly ...

Page 78: ...Technical Manual 78 Figure 35 10cm2 Digital Cone Assembly ...

Page 90: ...Technical Manual 90 ...

Page 91: ...Neptune 5000 Copyright Datem Limited 2014 91 Figure 45 Encoder Parts Drawing ...

Page 95: ...Neptune 5000 Copyright Datem Limited 2014 95 ...

Page 102: ...Technical Manual 102 ...

Page 104: ...Technical Manual 104 ...

Page 105: ...Neptune 5000 Copyright Datem Limited 2014 105 ...

Page 106: ...Technical Manual 106 ...

Page 107: ...Neptune 5000 Copyright Datem Limited 2014 107 ...

Page 108: ...Technical Manual 108 ...

Page 110: ...Technical Manual 110 ...

Page 111: ...Neptune 5000 Copyright Datem Limited 2014 111 ...

Page 112: ...Technical Manual 112 ...

Page 113: ...Neptune 5000 Copyright Datem Limited 2014 113 ...

Page 115: ...Neptune 5000 Copyright Datem Limited 2014 115 ...

Page 116: ...Technical Manual 116 ...

Page 117: ...Neptune 5000 Copyright Datem Limited 2014 117 ...