USER’S MANUAL

17

Chapter 5 ADJUSTMENT

Add oil and check the order of phase

.

After installing lift as Picture 4 required and connecting hydraulic circuit, electric

circuit and air loop, operate it as following:

-Open the hydraulic oil tank; add 18L of hydraulic oil into the oil tank, the hydraulic oil is

prepared by the user.

Make sure the clean of hydraulic oil, prevent any impurity into the oil line, lead the

digest of the oil line and no working of the solenoid air valve.

-Turn the “MAIN SWITCH” on power, click the “UP” button, and check whether

the motor turns clockwise (looking downward); if not turn off the power, change

the phase of the motor.

-Turn on air power.

When turn on power, the high voltage will exist in the control box, only authorized person can

operate it.

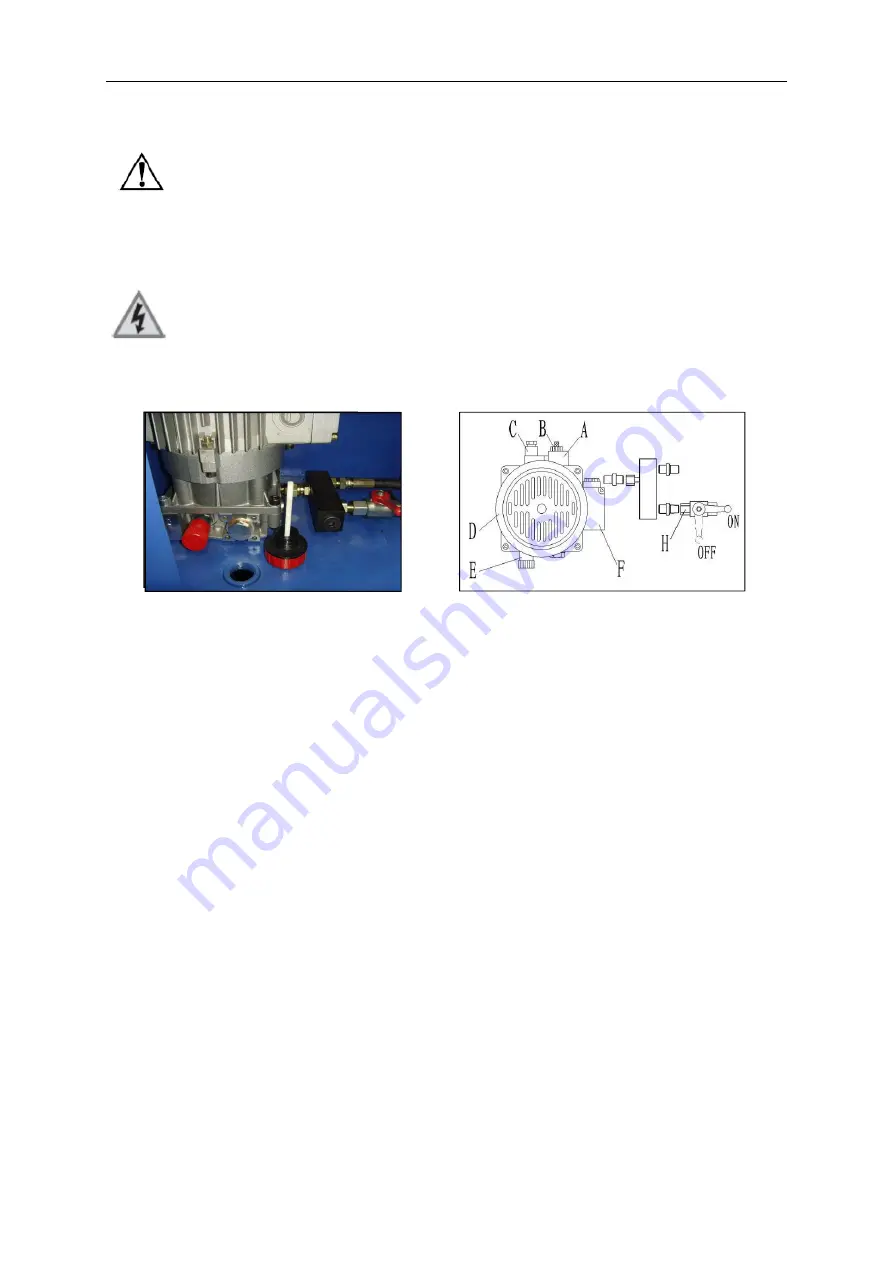

Main machine oil make-up adjustment

1 -Close the oil make up stop valve “H”

2 -Press “UP” button, and thus the left platform (looking from machine head direction) is

lifted to about 1000mm.

3 -Press the “DOWN” button to lower the left platform to the lowest position.

4 -Then lift it up to approximately 1400mm.

5 -Open the oil make up stop valve “H”.

6 -Press “UP” button, and the right platform (looking from machine head direction) is lifted to

about 1000 mm.

7 -Press “DOWN” button to lower the platform to the lowest position.

8 -Repeat the lifting and lowering process for 6-7 times to vent air automatically.

9 -Then lift the right platform to 1400mm. (The two platforms are lifted to the same height).

10 -Finally close the oil make up stop valve “H”.

Check

: oil leakage of the oil line and air tightness of the air loop.

Picture 20

Picture 21