We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this datasheet. The illustrations are not binding.

TANKS FOR FLUID FEEDING

The DAV Tech PT tanks are ideal to feed the valve DA 250.

They are available in 3 sizes 2, 5 and 10 liters and in different variations.

The tank PT2.0 in particular is designed to accommodate inside the 250 cc

oval containers used by the major manufacturers of anaerobic fluids such

as Loctite and Loxeal.

NOZZLES FOR VALVE DA 250

The valve DA 250 is designed to accommodate outlet nozzles with luer lock thread.

DAV Tech will be happy to advise and give you to test various types of nozzles in different materials and dimensions.

On request it is also possible to create special nozzles with various shapes.

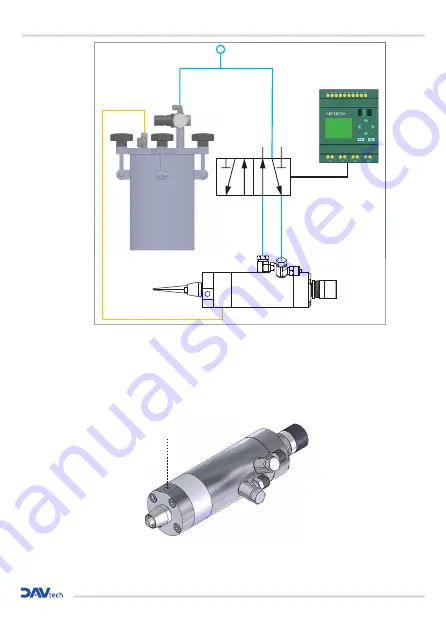

DRIVE VALVE DA 250

The valve 250 DA have to be drived by solenoid 5/2 or 3/2 (depending on whether you want to work double-acting or

simple acting) for a time setted by the PLC of the customer.

We are available for the supply of timing systems such as the DA 1000 T controller or even with the creation of

electrical control panels to manage the various I / O you need to check.

Connection diagram

S.V. 5/2

(ALSO POSSIBLE SINGLE

ACTING)

PLC

PRESSURIZZABLE

TANK

2.3 Connection diagram

3 INSTALLATION

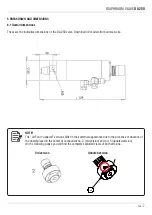

3.1 Mounting on the machine

The dosing valve must be mounted on a support by means of the special threaded hole (M5) on the valve, or by an

ad-hoc collar.

A good fixing of both the dosing valve to the support and the machine should be guaranteed without vibration and with

good accessibility for adjustment, cleaning and maintenance.

The ideal working position of the dosing valve is the vertical one, with the nozzle facing down.

Other positions are possible with the approval of DAV Tech

Threaded hole M5 for fastening

Installation and maintenance guide