4 MAINTENANCE

4.1 General rules

Minimal, simple, accurate, and constant maintenance allow for long-lasting and smooth operation in the dosing valve

time, while maintaining performance.

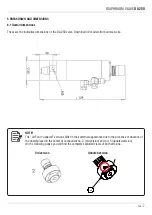

4.2 Valve Disassembly - Re-assembly

If it is necessary to disassemble the DA 250 valve, proceed as follows:

1) Disconnect the pneumatic supply

2) Disconnect the fluid supply after discharge

3) Remove the valve from the support to which it is attached

4) Remove the four M4 Allen screws on the front

5) Remove the front part of the PTFE section and clean them carefully

6) Remove the membrane by unscrewing it

7) Remove the 4 screws on the back

8) Pull out the piston, making sure not to squeeze the cylinder

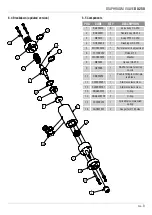

Before reassembling, following the procedure listed here replace the damaged parts (in addition to all the o-rings) by

helping with the explosion shown below.

5 TROUBLESHOOTING

5.1 Problems and solutions

Installation and maintenance guide

PROBLEM

POSSIBLE CAUSE

SOLUTION

Nothing or little adhesive Valve does not receive the command

Check the control (solenoid) of valve. Perform

a manual test.

The pressure of the adhesive is too low

or absent.

Check the pressure of the power supply fluid

and possibly increase it.

The nozzle is clogged

Remove and clean the nozzle.

The filter is dirty (if any)

Clean or replace the filter.

A tube is bent

Check the fluid supply pipe

Actuating pressure is not sufficient

Verify the actuation pressure (6 bar)

Residual fluid in the system to clean

Remove any solid particles

Flow of adhesive

compass

Moulded gasket damaged

Replace the molded seal

The nozzle drips also

if the valve is not pilot

Presence of dirt in the nozzle

Clean or replace nozzle

The valve opens late

Pressure drive is not enough

Check the operating pressure (6 bar)

O-ring on the piston damaged tire

Replace O-ring on the piston pneumatic