Installation and maintenance guide

> If the material is kept pressurised with no contact with the outside air, it can remain in the valve during long periods

without operation.

> Only clean, filtered material may be used.

5.2 Operating instructions

WARNING! Risk of hearing damage!

Hearing damage may result from the volume and length of exposure to noise.

Wear ear protection when working with the device!

WARNING! Risk of injury!

Housing parts with sharp edges and pointed corners can cause skin abrasions.

Wear protective gloves when working on the device!

WARNING! Danger!

If the spray parameters are not adequately adjusted, there is a risk of inhalation, contact with or

absorption of coating substances or cleaning fluids.

Always wear personal protective equipment when working on the device!

AIRLESS spray gun

Model S720

Copyright ALFRED SCHÜTZE Apparatebau GmbH,

2021. All rights reserved.

28

Doc-ID 1261

Operating instructions

➔

If the material is kept pressurised with no contact with the outside air, it can remain in the

valve during long periods without operation.

➔

Only clean, filtered material may be used.

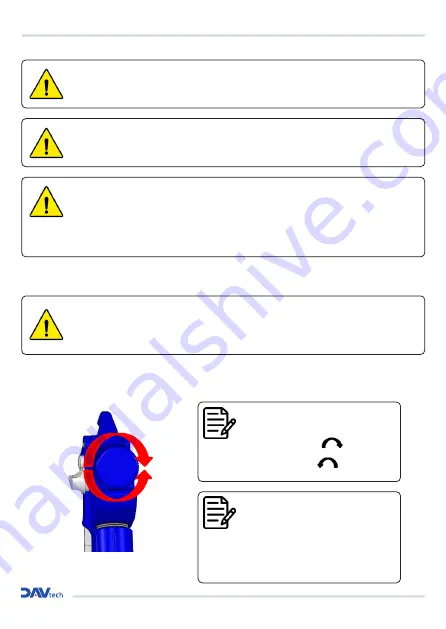

Fig. 5.2/1

WARNING! Danger!

If the spray parameters are not adequately adjusted, there is a risk of inhalation, contact with or

absorption of coating substances or cleaning fluids.

Always wear personal protective equipment when working on the device!

NOTE!

The flow of material can be adjusted to suit individual requirements by turning the regulating

screw (Item No. 8.1) (see Fig. 5.2/1):

Turn screw to the right:

to reduce the material flow

Turn screw to the left:

to increase the material flow

NOTE!

The illustrations in these instructions may differ slightly from the actual version of the device.

Incorrect handling can damage the nozzle and nozzle needle. Only reduce the material flow (by

turning the regulating screw to the right) while the material is being dispensed. Once the nozzle

closes, do not turn the regulating screw any further to the right.

NOTE! The flow of material can be adjusted

to suit individual requirements by turning the

regulating screw:

Turn screw to the right:

to reduce the material flow

Turn screw to the left:

to increase the material flow

NOTE! The illustrations in these instructions

may differ slightly from the actual version of

the device. Incorrect handling can damage

the nozzle and nozzle needle. Only reduce

the material flow (by turning the regulating

screw to the right) while the material is being

dispensed. Once the nozzle closes, do not turn

the regulating screw any further to the right.

WARNING! Danger from material and substances!

There is a risk of coming into contact with or absorbing coating substances and/or cleaning fluids.

There is also a risk of inhaling fumes from fluids. Under some circumstances, this can cause lasting

damage.

Always wear personal protective equipment when working on the device!

Make sure there is enough forced or natural ventilation.