4

DAVCO Technology, LLC

www.davco.com

800-328-2611

1600 Woodland Drive, Saline, MI 48176-1629

F1321 REV E

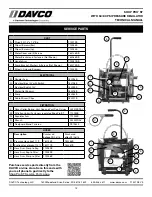

SHOP PRO

®

ST

WITH 50/80 PSI PRESSURE REGULATOR

TECHNICAL MANUAL

SET-UP AND MAINTENANCE

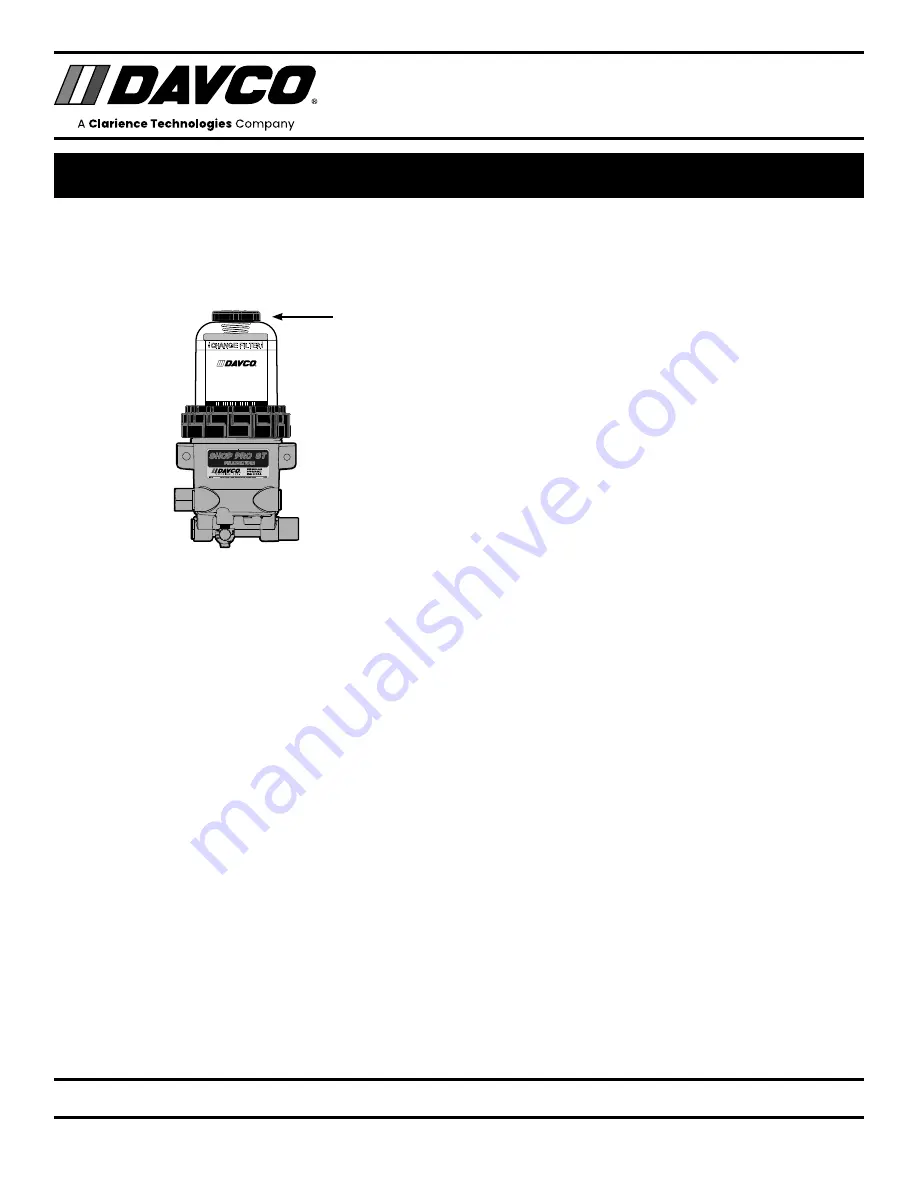

Set-up and First Use

1 . Unpack the Shop Pro ST and remove cable ties from

hoses .

2 . Remove the vent cap from the filtration unit .

3 . Pour diesel fuel into the clear cover until it reaches the

black band on the filter element . (This fuel will be on

the “dirty” side of the filter, meaning that the fuel will be

filtered before flowing through the Shop Pro ST to the

engine or tank .)

4 . Reinstall the vent cap and tighten by hand until it clicks .

The Shop Pro ST is now ready for use .

5 . Connect the Shop Pro to a power source . Install the

pick-up wand (green hose) and dispensing wand (red

hose) . Put the wands in a five gallon (minimum) fuel

container or truck fuel tank . Turn the Shop Pro power on

and circulate fuel until there are no bubbles in the sight

tube . Turn off the Shop Pro . Close the ball valves on both

hoses . Remove the wands from the hoses and return

them to their storage area . Connect the hoses to the hose

retainers . (Refer to photo on page 2 .)

Filtration Unit Maintenance

Drain Water

Water that has been separated from fuel will collect in the

bottom of the body of the filtration unit . Drain the water

periodically . The frequency will depend on how often the

Shop Pro is used and the quality of the fuel it has filtered .

1 . Open the vent cap slightly to break the vacuum . Place the

end of the drain hose in a suitable container and open the

drain valve .

2 . When only fuel is coming out of the hose, shut the valve .

Hand tighten the vent cap until it clicks .

Filter Replacement

Replace the filter in the filtration unit when there is low flow/

pressure or when the filter is visibly contaminated . The filter

change will also include replacement of the seals on the vent

cap and on the collar .

1 . Remove the vent cap and open the drain valve to drain

the fuel below the collar level . Close the drain valve .

2 . Remove the collar (use the DAVCO wrench) then remove

the clear cover . Remove the filter . Remove the seals from

the cover and the vent cap . Dispose of the filter and the

seals properly .

3 . Using a clean shop rag, clean the cover, vent cap, collar

and threads on the filtration unit body . Do not use any

acetone based cleaners on the clear cover .

4 . Install the new filter and the seals (included with the

replacement filter) .

Pro Tip: Write the date of the filter change with a permanent

marker on the filter wrap .

Pro Tip: Install the cover and collar on the filtration unit hous-

ing . Apply downward pressure on the top of the cover and

rotate the collar until contact . Use a DAVCO wrench to tighten

three additional ribs .

5 . Pour clean fuel into the filtration unit .

6 . Reinstall the vent cap and tighten by hand until it clicks .

Replacement filter part number:

Fleetguard: FS19624

Service Parts

See 13 for service parts . Call DAVCO customer service at

800-328-2611 to order .