3 INSTALLATION

3.1 Installation

- Installation of the device must be done

concerning installation distance determined

inside user manual.

- While installs the device; obey installation

distances determined above for making necessary

interferences easily in the future.

- The installation surface of the device must be

durable for carrying weight of device with water.

- Do not keep materials having risk such as

inflammable, explosive at the same place with

the device.

- In case of device installation wall is made of low

heat durable material (wood, etc), wall isolation

must be made suitable.

3.2 Plumbing

- Plumbing water hardness scale must not be

higher than 20F. In case of higher hardness scale

must be reduced. Damages that occur because of

hardness scale will make device out of warranty.

- Condensing outlet of boiler is located lower left

corner of the boiler. Condensing siphon must be

absolutely filled water before operation of the

boiler. Otherwise, exhaust gas that is formed

while combustion will leak to environment.

- Condensing outlet must be connected to

discharge line. Metal material must not be used

for discharge line. It must completely make of

from plastic materials. It can be followed by eye

that water inside the condensing line flows from

discharge. Any blockage inside condensing line

causes breakdown by failure of boiler. Do not

forget that this condition will be evaluated as out

of warranty.

- Be sure that plumbing is completely cleaned

before making plumbing connections.

- Installing valve to heating inlet and outlet of

boiler will provide convenience for processes that

will be made in the future.

- Your boiler’s operation pressure can be set max

6 bars. Be sure that plumbing pressure is at the

necessary range before operation.

- Internal circulation pump is located inside

boiler.

- In case of plumbing pressure is higher, it is

needed to put hydraulic separator between

plumbing and boiler.

- It must be expansion tank on the plumbing that

is chosen suitable to line. It must have automatic

air relief cock on the hydraulic separator and

discharge valve at bottom of hydraulic separator.

3.3 NATURAL GAS LINE

- Your device is compatible with NG and LPG

operation. At the product label it is written

about which gas it is needed to operate. Control

the correction of the gas type.

- Be sure that gas line pressure is at allowable

range.

- Be sure that gas pressure coming from plumbing

is at allowable range. In case of it is high, you

need to use pressure reduce regulator for

plumbing.

- There must be 1 pcs filter on the line for

protecting from dirt that may be come from line.

- Before first operation of the boiler, air of the

line must absolutely be taken.

Summary of Contents for Navidens 50

Page 1: ......

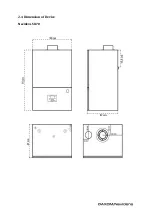

Page 6: ...2 4 Dimension of Device Navidens 50 70...

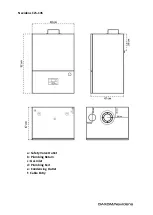

Page 8: ...2 5 Boiler Installation Distances...

Page 14: ...Concentric Pipe System Double Pipe System...

Page 15: ...4 Sample Installation Diagram 4 1 Heating System with Boiler...

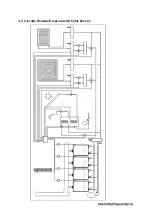

Page 16: ...4 2 Cascade Heating Diagram with Solar Energy...

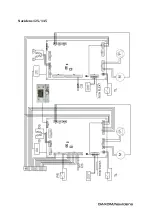

Page 18: ...6 ELECTRIC PROJECT Navidens 50 70...

Page 19: ...Navidens 125 145...