WARNING

Do not make the mixture leaner to achieve an apparent

increase in power – this could damage the engine.

Ÿ

Check chain tension frequently: A new chain has to be retensioned more often than

one that has been in use for some time.

Ÿ

Chain cold: Tension is correct when the chain fits snugly against the underside of the

bar and can still be pulled along the bar by hand. Retension if necessary –

see"Tensioning the Saw Chain".

This avoids unnecessary high loads during the break-in period. As all moving parts have

to bed in during the break-in period, the frictional resistance in the engine are greater

during this period. The engine develops its maximum power after about 5 to 15 tank

fillings.

Ÿ

Chain at operating temperature :The chain stretches and begins to sag. The drive links

must not come out of the bar groove – the chain may otherwise jump off the bar.

Ÿ

After long period of full-throttle operation: Allow engine to run for a short while at idle

speed so that engine heat can be dissipated by the flow of cooling air. This protects

engine-mounted components (ignition, carburetor) from thermal overload

WARNING

The chain contracts as it cools down. If it is not slackened off, it

can damage the gear shaft and bearings.

After Finishing Work

Ÿ

Slacken off the chain if retensioned at operating temperature during cutting work.

Ÿ

Storing for a short period Wait for the engine to cool down. Drain the fuel tank. Store

the machine in a dry location. Check the tightness of all accessible screws and nuts

(not adjusting screws) at regular intervals and retighten if necessary.

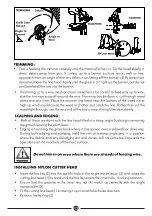

Taking Care of the Guide

Ÿ

Turn the bar over – every time the chain is sharpened and

every time it is replaced – this helps avoid one-sided wear,

especially at the nose and underside of the bar.

Ÿ

Regularly clean the oil inlet hole, the oilway and the bar. If

groove depth is less than specified: Replace the guide

bar.The drive link tangs will otherwise scrape along the

bottom of the groove –the cutters and tie straps will not ride

on the bar rails groove.

Ÿ

Measure the groove depth – with the scale on the filing

gauge (special accessory) – in the area used most for

cutting.

23