28

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

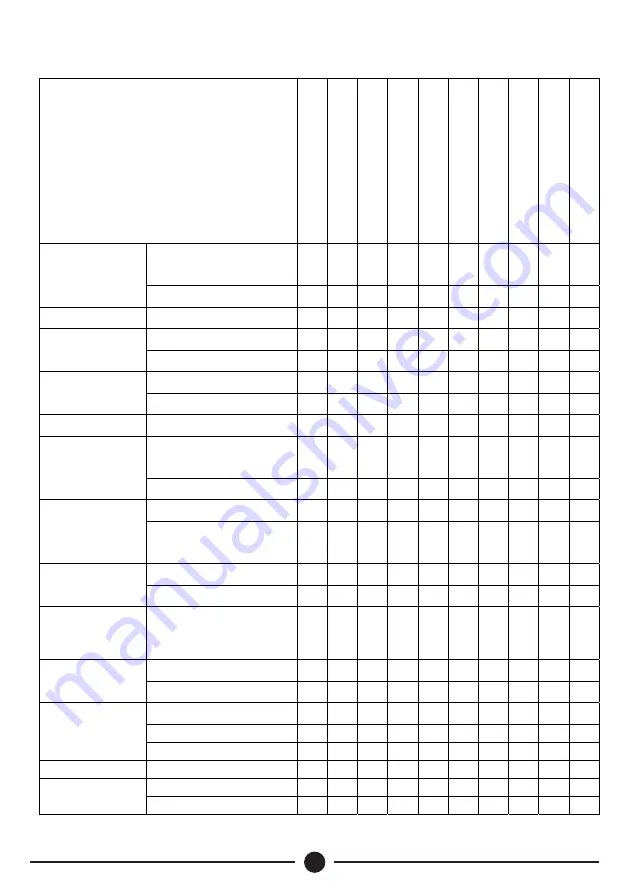

The following intervals apply to normal

operating conditions only. If the daily working

time is longer or operating conditions are

difcult (very dusty work area, etc), shorten

the specied intervals accordingly

Before Starting W

ork

Complete Machine

Visual inspection

(condition leaks)

After Finishing W

ork or Daily

After each R

efueling Stop

Daily Maintenance

W

eekly

Monthly

Every 12 months

If Problem

If Damaged

If R

equired

Control Handle

Check Operation

Air Filter

Pickup body in fuel

tank

Fuel Tank

Clean

Carburetor

Spark Plug

Cooling Inlets

All accessible

screws and nuts

(not adjusting

screws)

Antivibration

Elements

Chain Lubrication

Check

Guide Bar

Clean

Clean

Replace

Check

Replace

Check idle adjustment

Chain must not rotate

Readjust idle

Adjust electrode gap

Replace after every 100

operating hours

Visual inspection

Clean

Retighten

Check

Have replaced by dealer

Inspect, also check

sharpness

Check chain tension

Sharpen

Check (wear, damage)

Clean and turn over