5

3.2 Electrical Connections

WARNING

Electrical work to be carried out by competent

qualified and licenced electrician in strict conformity

to ruling national conditions and local regulations. All

wiring and external switchgear to comply with the

ruling local regulations in accordance with the latest

edition of IEE wiring regulations.

Ÿ

For the pump fuse protection use a 3 Amp fuse.

Ÿ

A means of disconnection from the power supply having a contact separation

of at least 3mm in all poles must be provided.

Ÿ

If the pump already has a cable fitted to it, ensure the pump is isolated from

the mains before removing the terminal cover.

3.3 Wiring Procedures

2

1. Use heat resistant 3x0.75mm core cable with rubber insulation rated at

0

110 C minimum.

2. Cut the cable to required length.

3. Remove the terminal cover.

4. Thread cable through grommet.

WARNING

The pump must be sufficiently earthed, else personal injury

may occur.

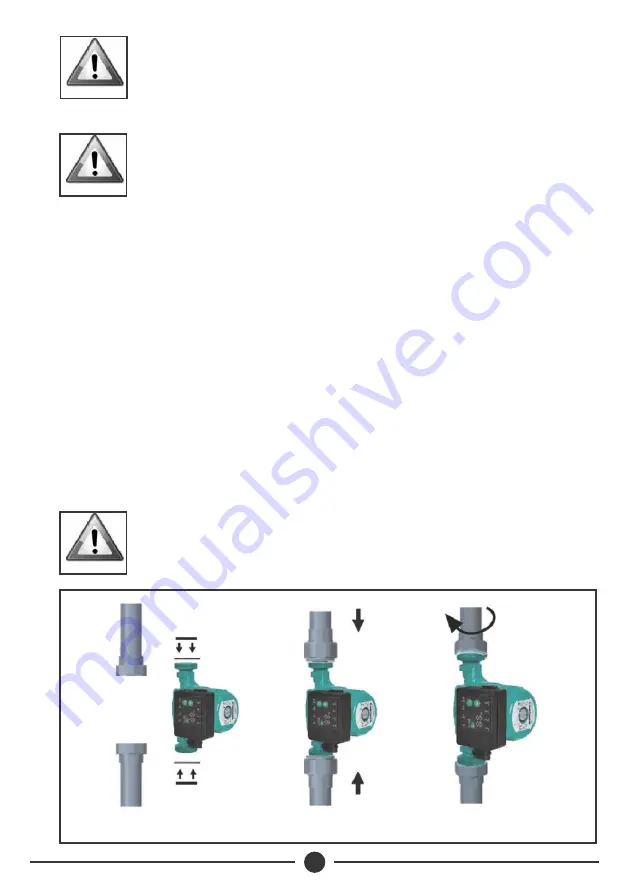

Step 1

Step 2

Step 3

NOTE

After use, the Manual Restart knob, should be

screwed back tightly into its original position.