PROTEC

AC-400 USER MANUAL V2.20

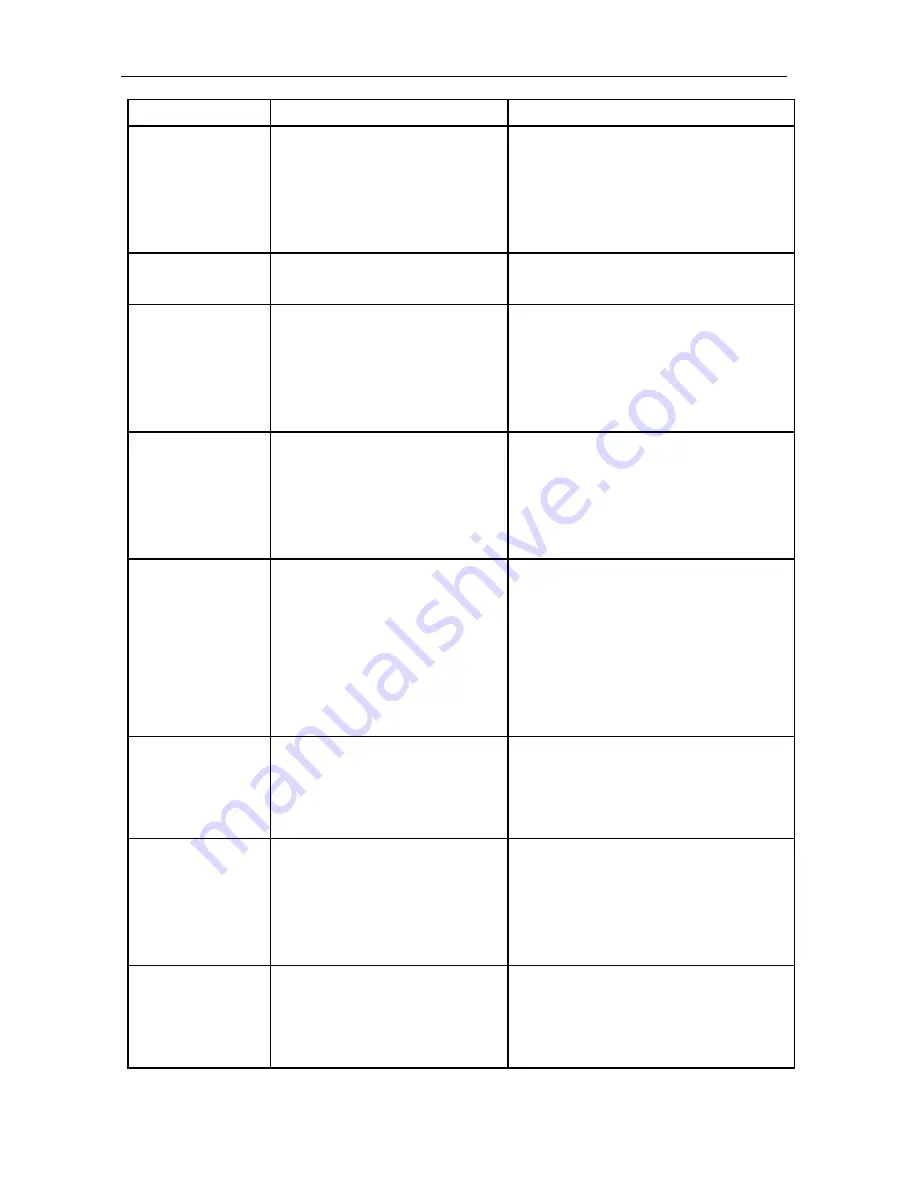

Main troubleshooting

Ma lf u n cti on

Reasons

So lu t ion

1.

Insufficient vacuum pump oil.

1. Add oil to central line

2.

Pump oil emulsion, dirty

2.

Put new oil

Low vacuum degree

3.

Pump oil inlet plugged.

3.

Clean oil inlet.

4.

Leakage in pump connection.

4.

Check connection

5.

Components worn out.

5.

Put new pump.

Vacuum pump inject

1.

Excessive oil volume.

1.Discharge oil to central line

oil.

2.

Entrance pressure too high.

2.Run Recovery function first.

1.

Fused (in Power cable connection

1.

Change fuses.

box, or PCA)

2.

Change PCA.

No display

2.

PCA burnt.

3.

Connect power cable reliably.

3.

Power cable loosened.

4.

Change LCD.

4.

LCD not work

1.

Leakage in automotive A/C or

Recovery

does

not

equipment pipeline.

1.

Make leakage test. Machine leakage test

2.

Compressor not work

with referenc to service manual.

stop

Remarks: In winter, it is normal

2.

Change compressor.

that recovery takes longer time.

1.

No refrigerant in A/C.

1.

Stop recovery.

2. Support screw of gas cylinder load

2. Unsrew the support screw in the bottom of

No

change

in

cell not loosened.

the weight sensor.

recovery volume

3.Gas cylinder load cell not work or

3.

Calibrate gas cylinder load cell, or change

PCA failure.

the load cell, or change PCA.

4.For RCC-6A, hand valves not

4.

Open RCC-6A HP/LP hand valves

opened.

While

auto A/C

has

1.

Low

pressure

switch

plug

refrigerant,

1.

Fasten low pressure switch plug.

equipment

displays

disconnected from PCA socket.

2.

Open RCC-6A HP/LP hand valves

2.

For RCC-6A, hand valves closed

alarm 005

High

pressure alarm

1.

High

pressure

switch

plug

004 but gas cylinder

disconnected from PCA socket.

1.

Fasten high pressure switch plug.

gauge does not show

excessive

pressure

2.

Pipeline

connecting compressor

2.

Change compressor exit side hoses.

exit blocked.

value

No charge

or slow

1.Insufficient

refrigerant

in

1. Add refrigerant to 5kg.

equipment

2.

Run recovery first.

charge.

2.System has pressure.

3.Check solenoid No5.

3.Charge solenoid not work.

22/24