22

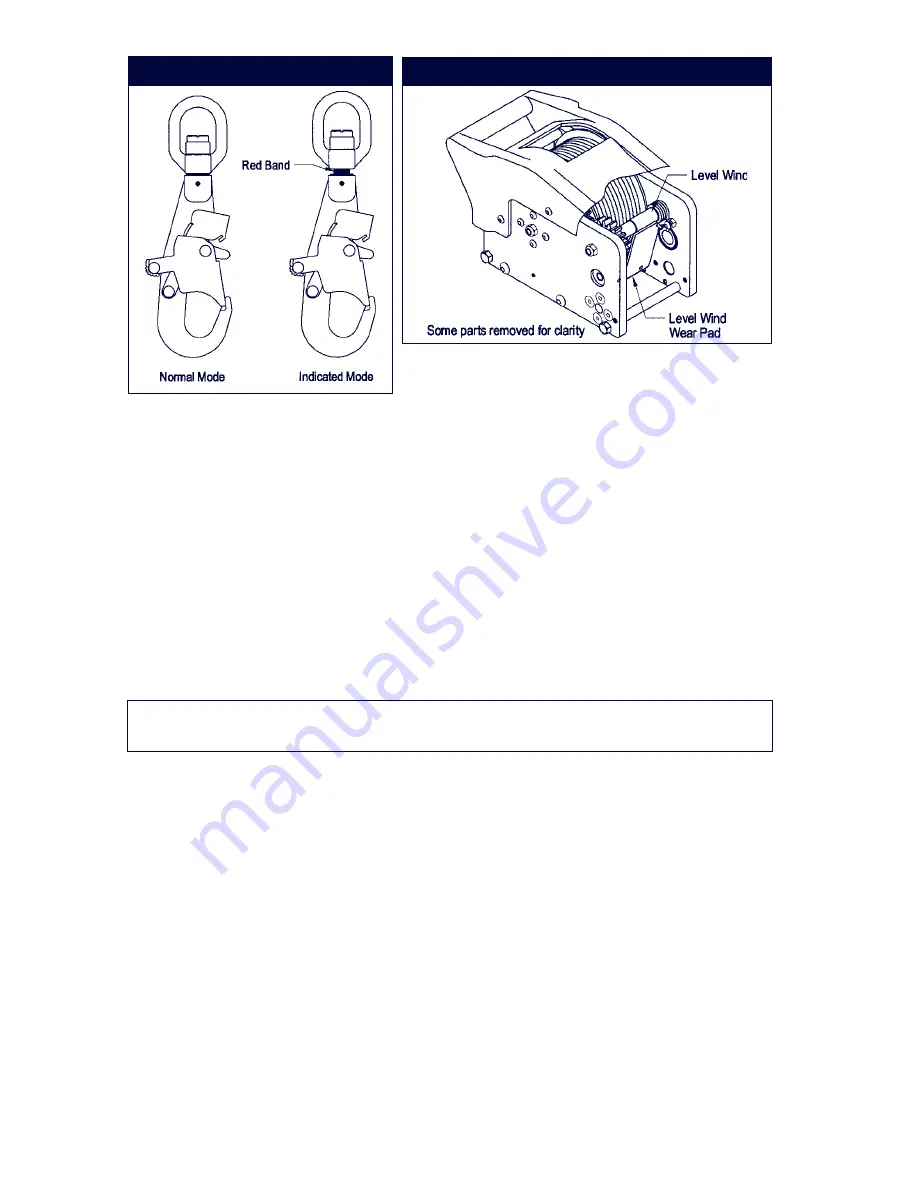

Step 3. See Figure 11. Inspect the impact indicator on the snap hook. If

the hook is in the indicated mode, return the winch to an

authorized service center for repair.

Step 4. See Figure 12. Inspect the level wind assuring that it moves

freely and applies pressure against the line. If the plastic wear

pad needs to be replaced return the winch to an authorized

service center.

5.5 If inspection or operation reveals a defective condition, remove the

winch from service immediately and contact an authorized service

center for repair.

NOTE: Only DBI/SALA or parties authorized in writing may make repairs to

this equipment.

6.0

MAINTENANCE, SERVICING, STORAGE

6.1 Periodically clean the exterior of the winch using water and a mild

detergent solution. Clean labels as required. At least twice a year, clean

and lubricate the wire rope. Do not use solvents to clean the wire rope

as they will remove internal lubrication. Lubricate wire rope using a cloth

(wearing gloves) and a light machine oil.

6.2 LUBRICATION OF SALALIFT WINCH;

• For the 8101000 series Salalift winch, the gear box contains eight

ounces of high quality gear oil, SAE 80 or 90. The oil does not require

changing unless there is evidence of contaminants in the oil. See

section 5.3, step 3. If the oil is contaminated or leaking contact DBI/

SALA for repair.

Figure 12 - Inspection level wind 8102000

Figure 11 - Impact Indicator

actoolsupply.com

actoolsupply.com