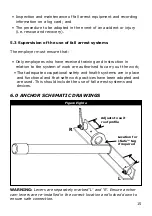

2.0 INSTALLATION

2.1 Installing Anchor on the Go™ on the roof

Step 1: Plan and prepare for the work to be undertaken. Complete a risk

analysis of the site to determine all the potential hazards. Consideration

should be given to work method statements, safe access, roof structure/

sheeting integrity, rescue procedure and so on.

Step 2: Inspect all equipment (Anchor on the Go™, Harness and any

associated Safety Equipment) prior to use to ensure it is within operating

period and is fit for purpose, free of damage etc. This process should

include a thorough inspection of structure to which the Anchor on the

Go™ will be installed. Refer to section 5.1 for inspection, care and

maintenance details.

Step 3: A safe means to access the intended temporary anchor installation

shall be provided.

Access to the roof will generally be by scaffold or ladder systems.

Scaffolding may only be erected, moved or disassembled by a competent

person and fall protection principles must be followed in those processes.

Further information can be obtained from AS/NZS 4576 Guidelines for

Scaffolding.

Where access is by ladder systems, the following items should be

checked:

• Inspect the ladder rungs and rails for any defects, cracks or corrosion.

• Never use a ladder with split or missing rungs or with oil or other

slippery material on the rungs.

• The ladder should be fitted with non slip feet.

• Place the ladder at a slope of 4 to 1, and secure at both the top and

bottom.

• Ascend and descend facing the ladder with both hands free to hold

the ladder.

• Always keep the area near the top and bottom of the ladder clear.

• Ladder side rails must extend 1m above the landing surface and be

7