i.

Check for broken wires

Pull the cable out in small segments

and flex to check for broken wires.

NOTE

The inspection of the cable is all

based on the definition of a lay, core,

strand and wire. A lay is where a

strand makes one complete

revolution around the core. The

core is the center of the cable itself.

A strand is the bundle of wires that

move around the core. A wire is a

single filament that makes up a

strand.

Start the inspection at the cable

clamp to check for broken wires or

strands. Pull out a short segment of

cable and turn it while flexing to

check for broken wires.

IMPORTMANT

Review the cable inspection log to

determine the location of previously

found broken wires or other defects.

These previously found defects

combined with those found during

this inspection may require that the

winch be removed from service.

Inspect the entire length of the cable

logging the results on the inspection

form.

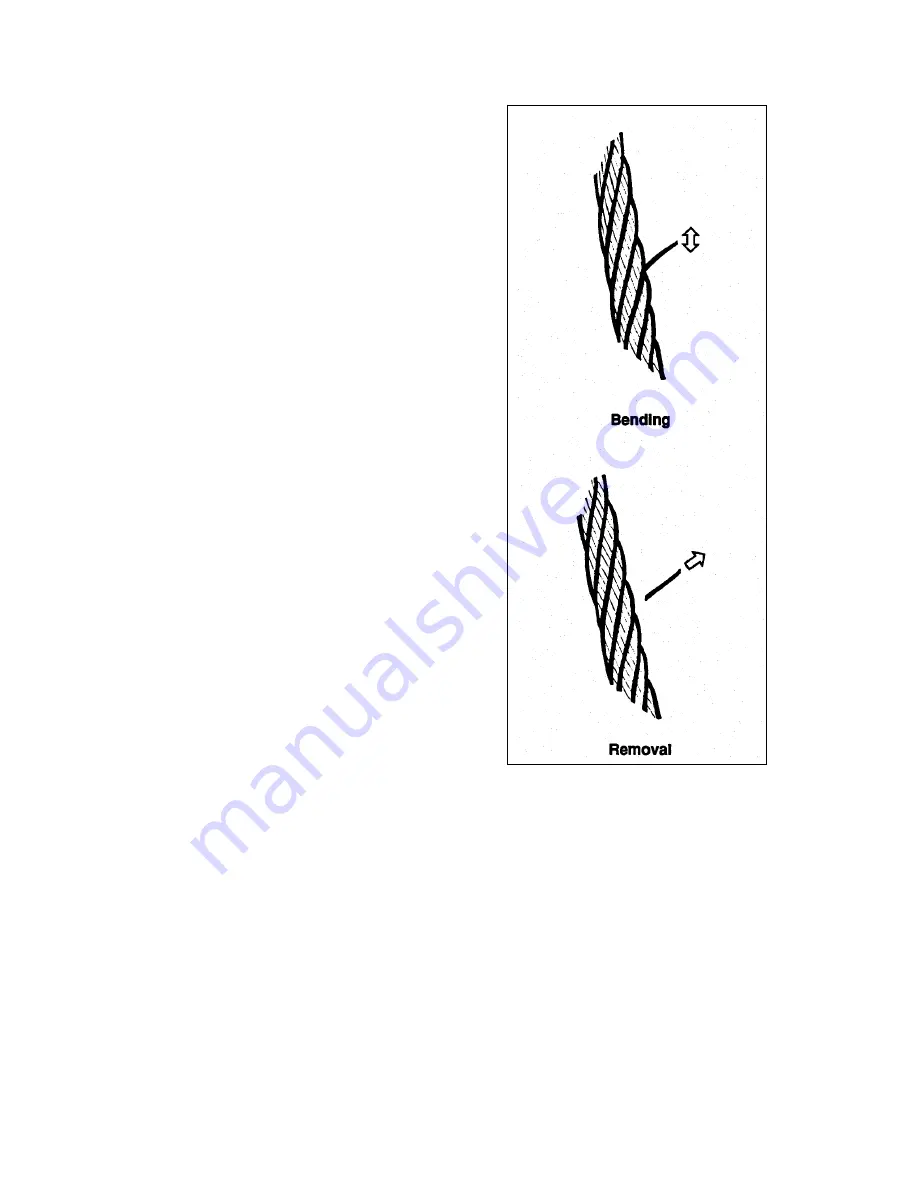

When a broken wire is found,

remove the protruding end by flexing

it back and forth along the length of

the cable. The wire will normally

break off inside the cable so there

are no exposed ends to damage

adjacent strands. Do not pull on an

end or wire with pliers. It can pull

the broken end out to expose it.

Figure 23 Broken Wire

31