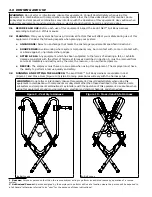

1.0 application

1.1.1 purpose: Suspension harness used for Fall

Arrest (D-Ring connections A, Figure 2) and Work

Positioning (D-Ring connections B, Figure 2).

1.2.1 standards: Refer to life safety harness

information found in NFPA 1500,

Standard on

Fire Department Occupational Safety and Health

Program

, and NFPA 1983,

Standard on Life Safety

Rope and Equipment for Emergency Services

.

Figure 2 - applications

A

A

B

2.0 system limitations & RequiRments

2.7.1 environmental hazards: Do not expose the harness to flame or high temperature. Such exposure

could cause the harness to melt or burn and fail during use. Harnesses that meet the optional flame

resistance requirements specified in NFPA 1983 are designed for use in environments where exposure to

flame or high temperature could occur.

3.0 Donning anD use

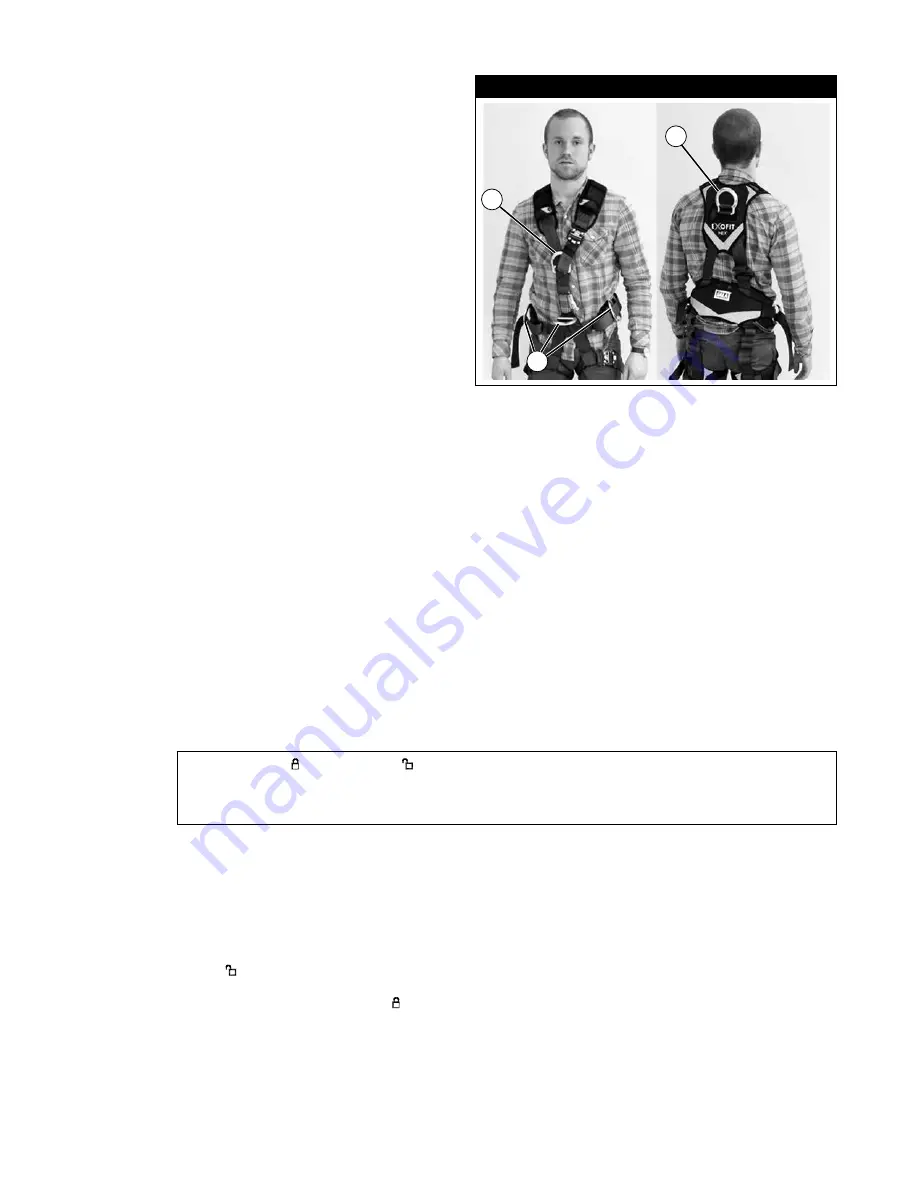

3.9 donning and Fitting the suspension harness: The ExoFit NEX™ Suspension Harness includes

leg straps for work positioning. Don the Full Body Suspension Harness using the following steps and the

corresponding images in Figure 3.

step 1.

Locate the front of the harness. The front has two D-rings. Lift up the harness and hold by the

shoulder straps. Ensure all straps are not twisted.

step 2.

With the front of the harness facing forward, step through the right side of the harness with

your right leg. Then, step through the left side of the harness with your left leg. Grasp the right

shoulder strap and place it on the top of your right shoulder. Ensure that the straps are not

tangled and hang freely.

step 3.

Grasp the left shoulder strap and place it over your left shoulder. The two D-rings will be

positioned on the front of your body if the harness has been donned properly.

step 4.

Grasp the tab of the buckle located at the bottom of the strap that you placed over your left

shoulder. Insert the tab into the receptor of the quick connect buckle on the left side of the

harness. You will hear a click when the tab engages properly.

note: Locking and unlocking the webbing lock prevents or allows the strap to slide

between the sliding bar and slot on the female end of the quick connect buckle. It does

not control engagement or disengagement of the buckle ends and will not affect the buckle

connection in the event of a fall.

step 5.

Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

step 6.

Reach between your legs and grasp the leg strap on your right side. Bring the strap up and

insert the tab of the buckle into the receptor of the buckle on the right side. You will hear a click

when the tab engages properly.

step 7.

Connect the right leg strap using the same procedure as in Step 6. To adjust the leg straps,

unlock the webbing lock on the quick connect buckle and pull on the strap. A plastic end

keeper on the end of the strap will stop it from pulling completely out of the buckle. When the

strap is properly adjusted, lock the webbing lock. To release the buckle, press the silver-colored

tabs on the buckle towards each other with one hand, while pulling on the tab portion of the

buckle with the other hand.

step 8.

Adjust shoulder straps to a snug fit using the strap adjustment procedure described between

Steps 4 and Step 5 on the following page. Left and right sides of the shoulder straps should be

adjusted to the same length and the upper front D-ring should be centered on your lower chest.

The back D-ring should be centered between your shoulder blades. Adjust the leg straps to a

snug fit. At least 3 in. (8 cm) of webbing must extend past the buckle on the leg straps. Adjust

the waist belt again as necessary for a secure, comfortable fit.