Unpacking

1 www.dcionline.com

C1000 Series Service & Maintenance Manual

Maintenance

Maintenance

SECTION III

Unscrew the

fi

lter bowl by turning counter-clockwise. Lower the

fi

lter bowl to access the

fi

lter element contained inside. The

fi

lter element is held in place with an O-ring and

internal ridges located in the bowl. Replace with DCI Part Number 2006, and reassemble

the

fi

lter bowl. Turn the dryer bypass valve to the ON position and check compressor for

proper operation by turning the power switches on.

NOTE: A “popping” relief valve indicates a clogged coalesing element OR

the Dryer Bypass valve is closed.

B. Coalescing Filter Element

The coalescing

fi

lter element should be checked with the compressor motors running. If

the indicator located on the top of the

fi

lter housing remains GREEN, the

fi

lter element has

additional useful life. However, if the indicator turns RED, the element should be changed.

To change the element,

fi

rst turn off the compressor motor switches. Then turn off the

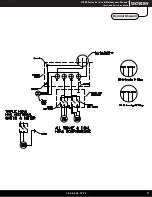

Dryer bypass valve as shown in (Fig. E). With dryer bypass valve in OFF position, press the

TEST button on the time operated purge valve to bleed pressure off of the drying system.

Depressurization of the drying system can be con

fi

rmed by reading the drying system

pressure gauge located on top of the drying chamber.

WARNING

: DO NOT ATTEMPT TO SERVICE WITH SYSTEM PRESSURIZED.

Fig. D

Fig. E

ON

OFF

COMPRESSOR MAINTENANCE SCHEDULE

Maintenance Item Frequency

Intake Filter Elements

Every Six Months (semi-annually)

Coalescing Filter Element

Every 90 Days

Time Operated Purge Valve

Every 60 Days

Tank Drain

Every 90 Days

A. Compressor Head Intake Filter Elements

Dirty intake

fi

lter elements reduce the amount of air the compressor can take in. This

reduces air output and increases the load of the motors. Every six months, remove

the intake

fi

lter cover as shown in (Fig. D), to check for excessive dirt or discoloration.

Replace with DCI Part Number 2012 if needed. The

fi

lters are located on the rear of each

compressor cylinder.

MAINTENANCE

w w w.dcionline.com

8