4

Features

• Weatherproof

• All High Heat Parts Made Of Stainless Steel

• Uniform Heat Pattern

• Flame Out Protection Safety Control Valve

• Durable Non-Slip Wheels

• Weighted Base For Stability / Low Maintenance

• Piezo Spark Ignition

• Easy Access Door With A Positive Latch

• Heats (16’-20’) Diameter Area

• Large Stainless Steel Emitter Grid

• Uses 13 kg LP Tank (not included)

• Easy Access Door With A Positive Latch

TOOLS NEEDED

• Phillips Head Screwdriver

• Channel Lock Pliers (Min. 2” Capacity)

• Pipe Wrench ( 2” or larger)

• Open End (7/16”, 3/4”, 7/8”, and 15 /16” Wrenches

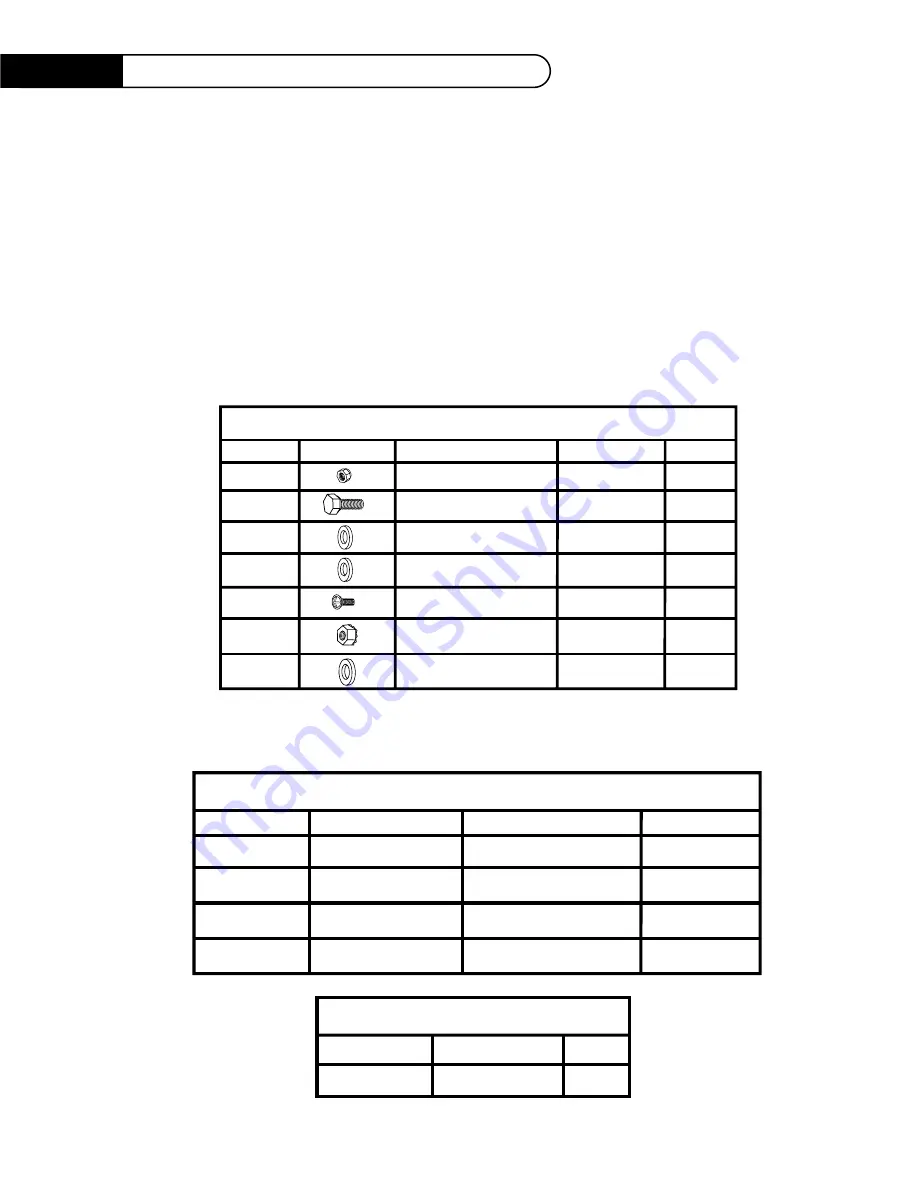

FASTENER DIRECTORY

ITEM

PICTORIAL

DESCRIPTION

QTY.

1

2

3

5

6

1/4-20 ACORN NUT

1/4-20 BOLT

WASHER - FLAT - SS

1/4-20 KEPS NUT

8

4

12

3

12

7

8

no. 10 - 24 X 1/2

S/S SCREWS

NYLON WASHER

PART NUMBER

15019-02

15003-06

15005-15

4

WASHER - SPLIT - SS

4

15005-10

15021-09

15001-26

15005-08

SPECIFIED CATEGORY AND DELIVERY PRESSURES:

GAS CATEGORY

OPERATING PRESSURE

COUNTRY

1 3P

37 mbar

50 mbar

30 mbar

50 mbar

NL, ES

DK, SE, FI, NL

FR, DE, CH, AT

1 3P

1 3B/P

1 3B/P

INJECTOR SIZE

GB, IE, FR, BE, PT, ES, CH

50 DMS

52 DMS

50 DMS

53 DMS

UNIT GROSS INPUT RATING

G31 PROPANE

43,000 Btu / hr

12.6 Kw

43,000 Btu / hr

12.6 Kw

G30 BUTANE

GAS SPECIFICATIONS