Unit 5: Troubleshooting

SATO MB200 Operator Manual

PN 9001126A

Page 5-2

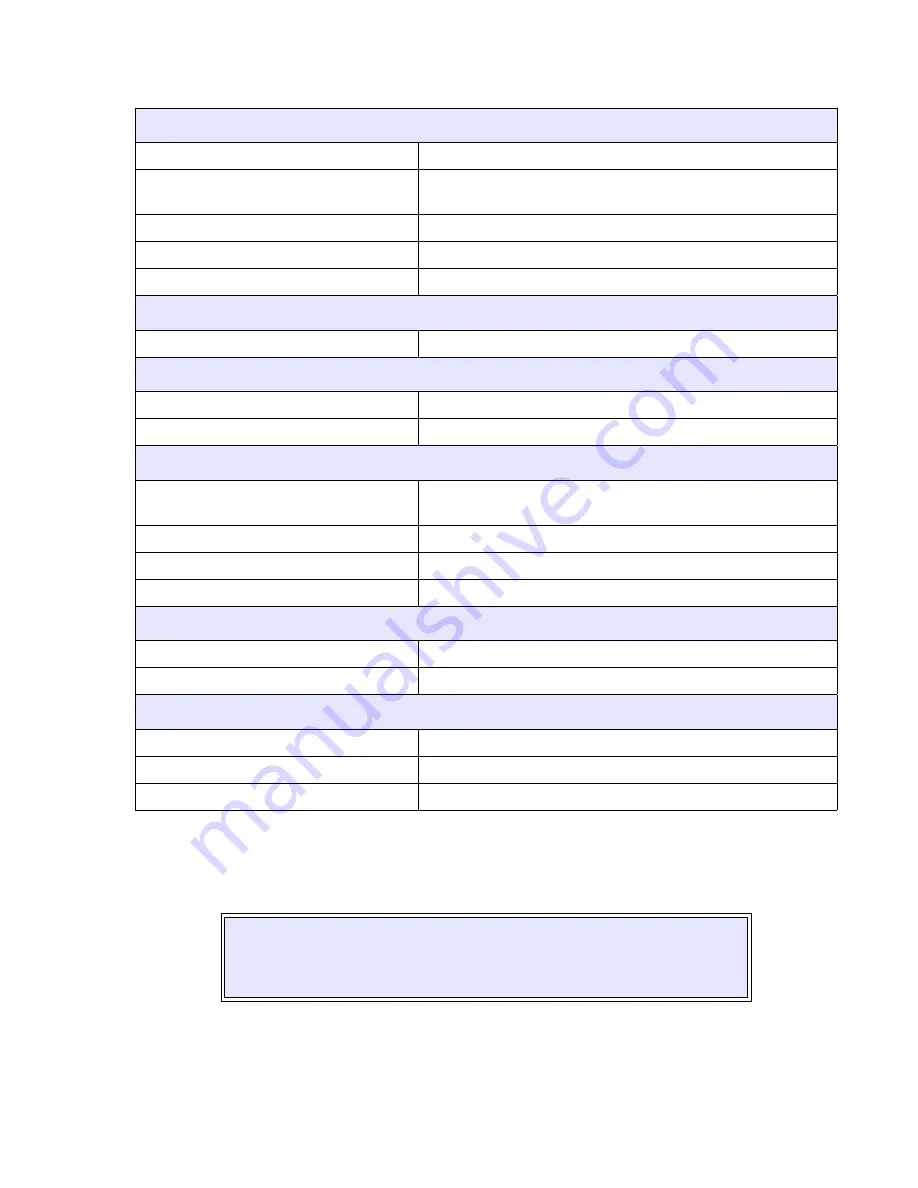

RS232 SERIAL INTERFACE TROUBLESHOOTING

•

Ensure the serial cable is thoroughly connected to the PC and the printer.

•

Ensure the serial cable is not defective and that it is manufactured to specifications.

•

Ensure the RS232 Interface Module is properly installed.

SMEARED PRINT IMAGE

Poor label quality.

Use high quality direct thermal label stock.

Foreign material on print head and platen

roller.

Clean print head and platen roller.

Foreign material on labels.

Use high quality label stock.

Excessive print head energy.

Adjust darkness control.

Excessive print speed.

Adjust speed as required.

FUZZY PRINT IMAGE

Heat too high.

Adjust as required.

NO LABEL MOVEMENT

Loose or broken platen drive gears.

Adjust or replace platen drive gears as required.

Incorrect label pitch sensor selected.

Select the correct label sensor type.

NO PRINTED IMAGE

Print head is disconnected.

Ensure that print head wiring harness is connected on each

end.

Low voltage output.

Test power supply voltage and replace as necessary.

Damaged print head.

Replace print head.

Damaged electronics.

Replace circuit board.

POWER LED NOT ILLUMINATED

AC power cable disconnected.

Ensure the cable is connected at each end.

Defective power supply.

Test with meter and replace as required.

WILL NOT GO ON-LINE

Defective power supply cord.

Ensure proper function or replace.

House power supply discontinued.

Test receptacle.

Battery pack power depleted.

Recharge or replace.

CAUTION:

NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

PRINTER OR THE HOST. THIS MAY CAUSE DAMAGE TO THE INTER-

FACE CIRCUITRY AND IS NOT COVERED BY WARRANTY.