42

™

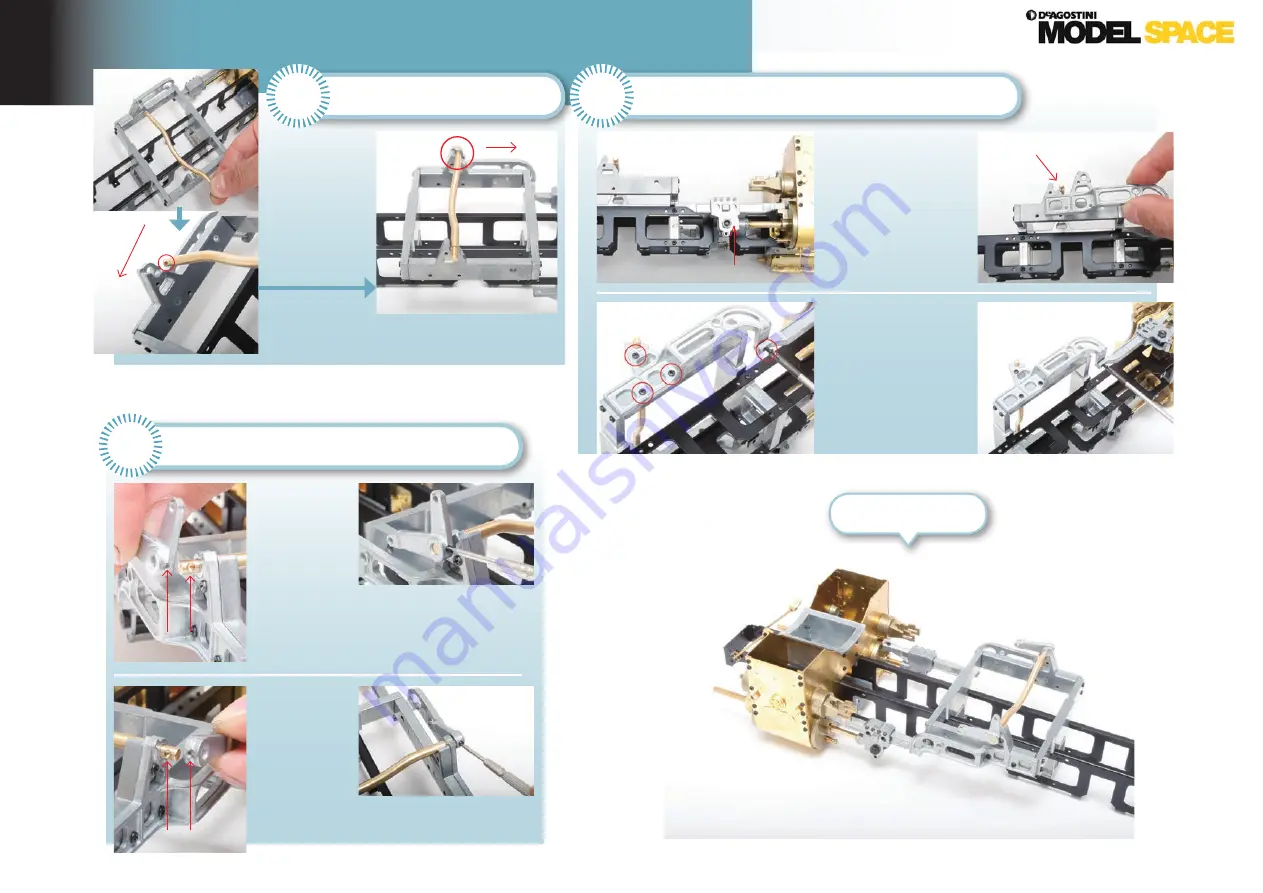

Fitting the reverse shaft

Assembling the motion plate

2

3

Fitting the reverse link

4

Assembled parts

Rear

Front

Crosshead

Reverse shaft

Align the holes

Align the holes

Hold the shaft

over the motion

frame and turn

it so the hole at

the end (circled,

left) is facing

towards

the rear.

Re-fit the right crosshead

into position.

Half-tighten a

2 x 6mm screw

into each of the

circled holes.

Place the left

reverse link

over the left

side of the

reverse shaft,

aligning the

holes of both.

Tighten one of the 2 x 2.6mm

screws into the hole of the link

to secure it to the shaft.

Tighten a 2 x 2.6mm screw into

the hole of the link.

Place the right

reverse link

over the right

side of the

shaft, aligning

the holes.

Place the right

motion plate over

the right side of the

motion frame, so

that the screw holes

align and the shaft

protrudes through

the hole.

Ensure that the

shaft can rotate

smoothly, then

tighten all the

screws fully.

Insert the end of the shaft into the hole

in the left motion plate (circled, above).