48

™

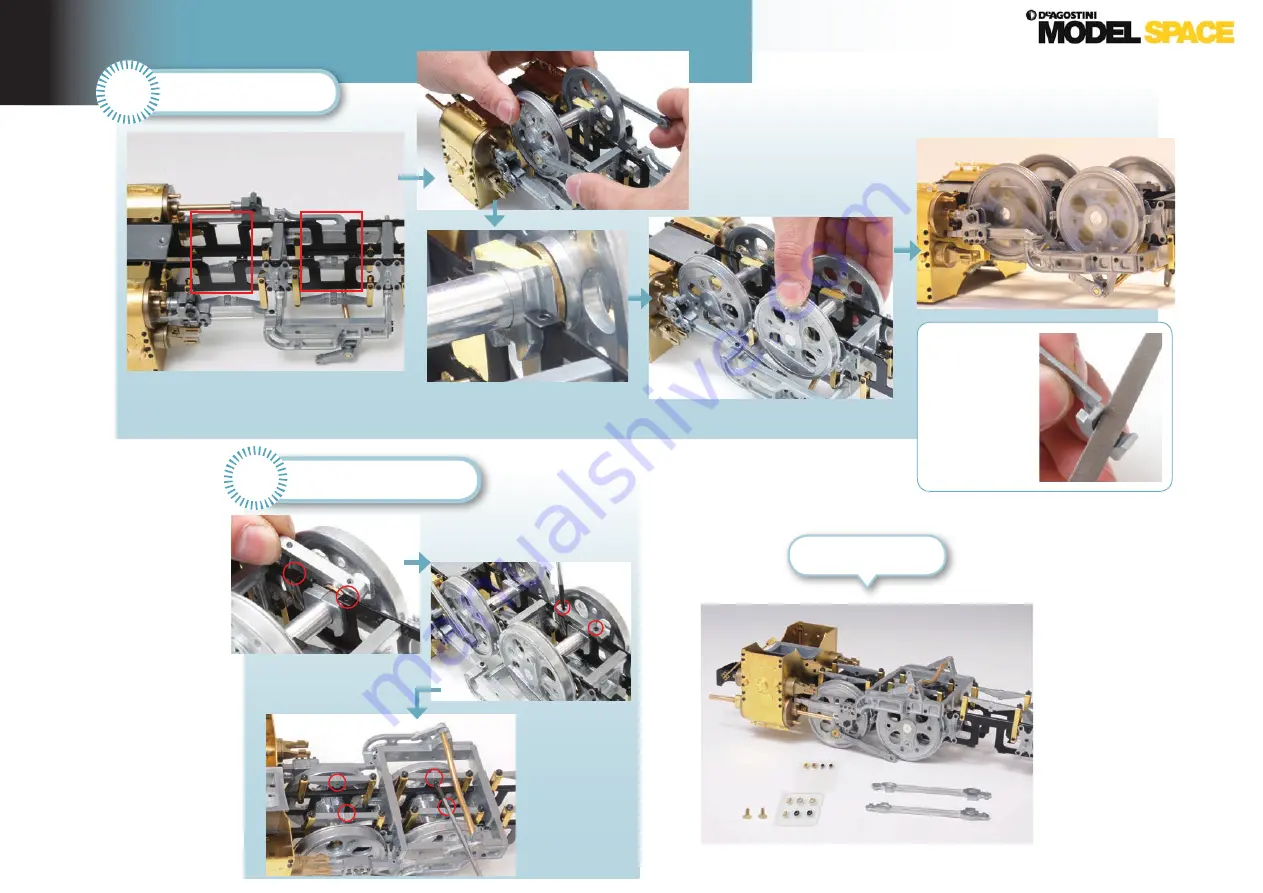

Assembled parts

2

Fitting the wheels

3

Fitting the guards

Tip!

Turn the assembly over and locate the two

U-shaped cut-outs on the underframe.

Fit the wheel assembly from this stage into

the second cut-out. Remove the tape.

Position the wheels so that the

underframe rests in the groove of

the axle boxes.

If the wheels don’t

rotate smoothly,

then check the

inside edges of the

axle boxes for any

burrs. Remove any

found with a half-

round file.

Place the wheel assembly from

Stage 4 into the cut-out at the

front of the underframe.

Once both wheel sets are in position,

rotate them to check that the movement

is smooth. Be careful of the coupling rod.

Place an axle box guard onto

the underframe, aligning the

holes with those circled.

Tighten a 2 x 6mm

screw into the two holes

on the axle guard, securing it in

place. Repeat this process for the

remaining three guards.

Turn the assembly

back over and

tighten a screw

into the circled

holes on the leaf

springs to secure

them to the

ends of the long

parts of the

axle boxes.