115.6031.0

- 10 -

1.3

Component Description

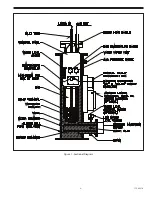

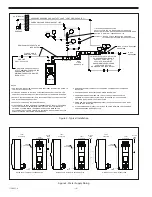

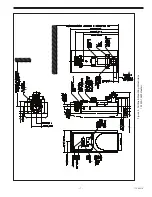

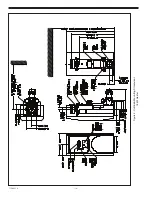

Refer to Figures 1, 2, 3, 4 and 5 to supplement the following text.

1.3.1 General

In addition to the components described in Section 1.3.2, which comprise the Basic Vaporizer Unit,

all Vaporizer Systems should be piped and valved to include the auxiliary components as shown in

Figures 2 and 3.

1.3.2 Basic Vaporizer Unit

1.3.2.1 Water Chamber

The water chamber provides uniform distribution of heat around the outer surface of the

vaporizing chamber wall. The chamber’s outer surface is covered with closed cell foam

insulation to minimize radiant and convective heat losses.

1.3.2.2 Vaporizing Chamber

The vaporizing chamber receives the liquid chemical from its source and converts it into the

gaseous state at a rate equal to the demands of the using system. This chamber contains an inlet

tube and superheat baffle which function as described below to provide the essential

operating requirements of the vaporizing system.

a.

Inlet Tube: The inlet tube, which extends to the lower portion of the chamber, serves to

provide both forward and reverse flow of liquid chemical to and from the chamber; thereby,

automatically regulating the level of liquid chemical in the chamber to increase and decrease

the liquid contact area, and hence the rate of evaporation, in accordance with the demands of

the overall system.

b.

Superheat Baffle: The superheat baffle, which extends a short distance downward from the top

of the chamber, serves to force the gas to travel along the hot wall of the chamber as it passes

from the surface of the liquid to the outlet; thereby, superheating the gas, i. e., increasing its

heat content at the existing pressure within the chamber, prior to its discharge to the gas

distribution system.

1.3.2.3 Water Level Gauge

The water level gauge provides visual indication of the water level in the water chamber.

1.3.2.4 Electric Immersion Heater

The electric immersion heater supplies the heat required to maintain the temperature of the water

in the water chamber at the desired operating value.

1.3.2.5 Magnetic Heater Contactor

The magnetic heater contactor acts in response to the water temperature controller to energize and

de-energize the electric immersion heater. This component, although essential to the operation

of the Vaporizer, may not have been supplied unless specifically requested. This may have been

due to site specific electrical design criteria requiring that the contactor be mounted in a centrally

located motor control center.

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...