- 15 - 115.6031.0

Heat tracing of the pipe section between the Vaporizer and pressure reducing valve may also be advisable to

maintain the gas superheat temperature. This is especially true for Sulfur Dioxide service. Refer to the super heat

curves further in this manual. Note also that the addition of a gas filter in this pipe section will act as a heat sink

further reducing the super heat temperature.

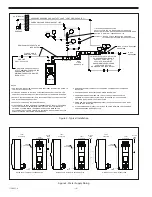

As illustrated in Figure 2, the emergency and servicing vent line must be connected to the gas discharge line using

a “Tee” coupling. This connection should be made at some point between the Vaporizer outlet and the first

shut-off valve in this line. This vent line, as well as the diaphragm rupture vent line, must be extended to a suitable

area (outside the building for indoor installations) where gas fumes cannot cause damage or endanger operating

personnel. These lines must be arranged to prevent low spots where condensed water vapor could be trapped.

Their ends must be turned downward to keep out water and a fine mesh plastic screen installed over their outlets to

prevent the entrance of insects.

2.1

Electrical Interconnections

Control circuit protection (provided by user) shall not exceed 15 amperes.

Information pertaining to the wiring interconnections that must be made to the terminal strip in the

control circuit connection box is provided on the Wiring Diagram(s) furnished with these instructions.

The Wiring Diagrams shown in Figures 6 through 9 provide typical versions of the function and

operation of the various control and/or alarm circuits.

2.2 Heater Connections

In accordance with the National Electrical Code (NEC), NFPA 70, Article 424-70, Resistance-type Boilers, branch circuit

wiring to the heater contactor shall be rated at 125% of the rated heater current. Branch circuit protection may be

the next higher current rating over the actual heater current, not to exceed 60 amperes. The equipment ground

conductor run and the service conductors must be in accordance with Table 250-95 of the National Electrical Code.

Refer to the Wiring Diagram(s) furnished with the equipment and to Figures 6 through 13.

WARNING

Electrical Shock Hazard. AC powered electrical equipment presents a potential shock hazard.

Installation and servicing should only be performed by qualified personnel.

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

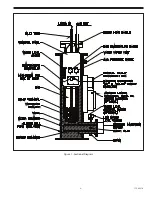

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

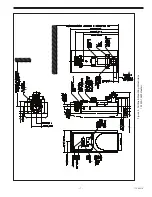

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

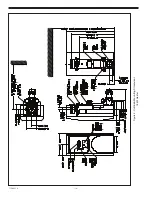

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...