115.6031.0

- 16 -

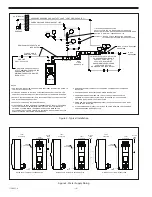

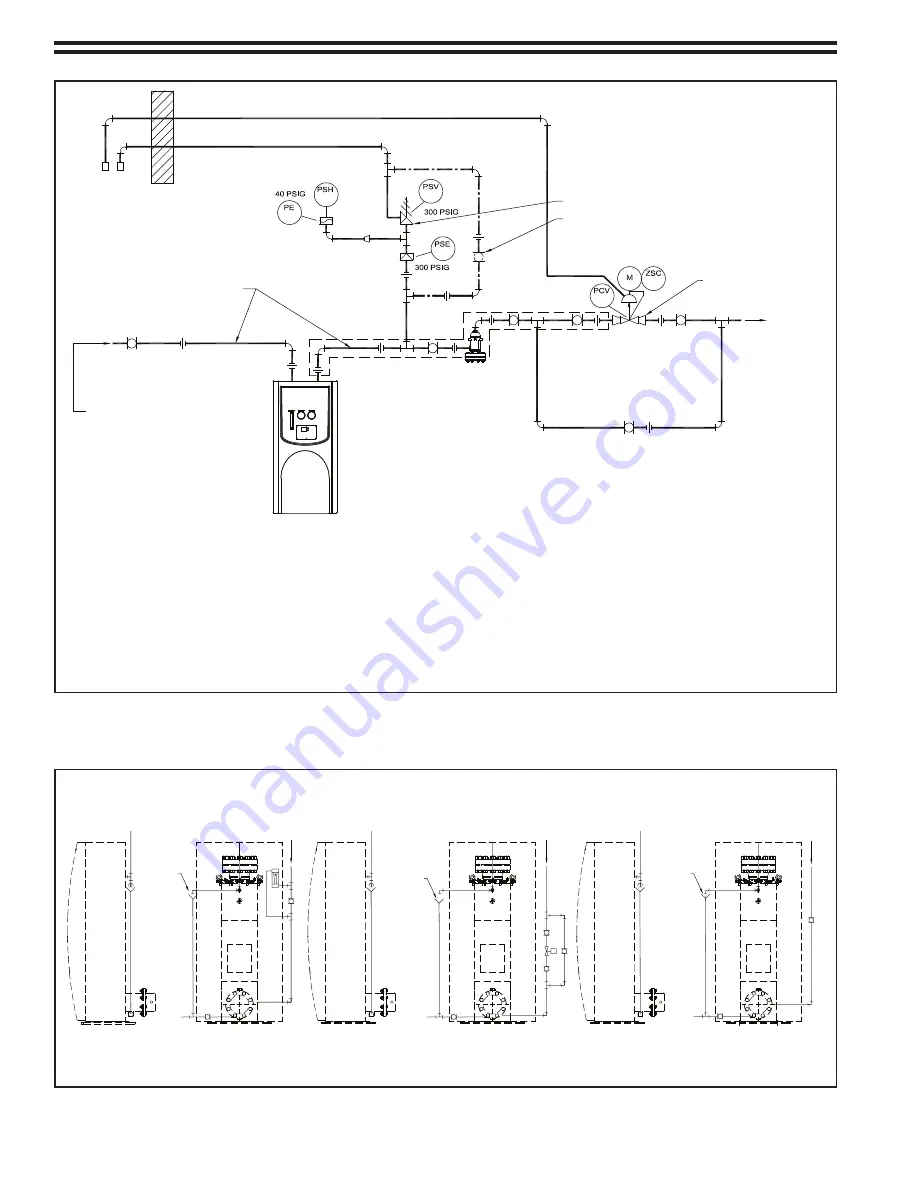

Figure 2 - Typical Installation

Figure 3 - Water Supply Piping

WATER

FEED

INLET

VENT/

OVERFLOW

TO

DRAIN

WATER SUPPLY PIPING WITH PURGE METER

WATER SUPPLY PIPING WITH SOLENOID VALVE

DRAIN

TO

WATER

FEED

INLET

S

WATER SUPPLY PIPING - MANUAL FEED

OVERFLOW

VENT/

VENT/

OVERFLOW

AIR GAP

REQUIRED

REQUIRED

AIR GAP

OVERFLOW

VENT/

TO

DRAIN

REQUIRED

AIR GAP

VENT/

OVERFLOW

OVERFLOW

VENT/

INLET

FEED

WATER

3/4 INCH ELECTRICALLY-ACTUATED

PRESSURE REDUCING AND

SHUT-OFF VALVE. SET AT

1 X 1/4

AND AMMONIA SERVICE AND

40 PSIG FOR CHLORINE

DIOXIDE SERVICE. (SEE NOTE 8)

15 PSIG FOR SULFUR

SHUT-OFF VALVE

PIPE LINE

(AMMONIA TYPE)

FLANGE UNION

INSULATION

EMERGENCY AND SERVICING VENT LINE

VENT LINE (SEE NOTE 7)

PRESSURE REDUCING AND SHUT-OFF VALVE

OUTSIDE WALL

INSECT

SCREENS

NOTES:

1. FOR LOCATION, MOUNTING AND ADDITIONAL PERTINENT INFORMATION, REFER TO

THE INSTALLATION SECTION.

2. PIPING AND FIXTURES TO BE 1 INCH 25 MILLIMETERS, EXCEPT AS NOTED, AND

CONSTRUCTED OF MATERIALS SUITABLE FOR CHEMICAL SERVICE IN QUESTION,

3. REFER TO INSTRUCTION BULLETIN 010.3650 FOR MATERIALS OF CONSTRUCTION

AND INTERCONNECTION PRACTICES.

4. SUPPORT ALL PIPE RUNS THEIR ENTIRE LENGTH.

5. AIR PADDING AT SOURCE REQUIRED IF TEMPERATURE OF SUPPLY IS EXPECTED

TO FALL BELOW SPECIFIED MINIMUM. PADDING TO BE 40 PSIG MINIMUM FOR

CHLORINE, 50 PSIG MINIMUM FOR AMMONIA AND 35 PSIG MINIMUM FOR

SULFUR DIOXIDE; 100 PSIG MAXIMUM, ALL INSTANCES. SEE CHLORINE INSTITUTE

6. REQUIRED TO PERMIT REMOVAL OF VAPORIZING CHAMBER FOR CLEANING AND

INSPECTION.

7. LINE SIZE BASED ON MANUFACTURERS' RECOMMENDATIONS.

8. PIPE RUN BETWEEN VAPORIZER AND THIS VALVE SHOULD BE AS SHORT AS

POSSIBLE, WITH HEAVY INSULATION (2 INCH THICKNESS TYPICAL) AS SHOWN.

ALL OTHER PIPES TO BE WITHOUT INSULATION.

9. PIPING SHOWN IS FOR RECOMMENDED INSTALLATION PURPOSES ONLY, AND IS NOT

SUPPLIED WITH VAPORIZER.

VAPORIZER

REMOVABLE PIPE SECTIONS

(SEE NOTE 6)

TO GAS

VALVE MUST BE LOCKABLE IN CLOSED POSITION.

OPTIONAL: 1 INCH OR 1/2 INCH BYPASS LINE AND VALVE.

SECTION 13, DIVISION 1, PARAGRAPH UG-125

MANDATORY BY ASME BOILER AND PRESSURE VESSEL CODE

SET AT 300 PSIG FOR ALL THREE CHEMICAL SERVICES.

1 INCH PRESSURE RELIEF VALVE.

1 INCH X 3/4 INCH REDUCERS,

IF REQUIRED

PAMPHLET #66 FOR AIR PADDING REQUIREMENTS.

10. IT IS RECOMMENDED TO INSTALL AN IN-LINE GAS FILTER BETWEEN THE VAPORIZER

AND THE PRESSURE REDUCING VALVE.

(SEE NOTE 10)

GAS

FILTER

DISPENSERS

FROM LIQUID CHEMICAL SUPPLY

AT 32°F MINIMUM FOR CHLORINE

AND AMMONIA AND 70°F

MINIMUM FOR SULFUR DIOXIDE.

(SEE NOTE 5)

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

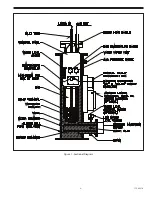

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

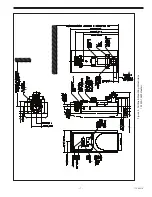

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

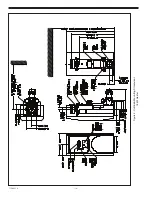

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...