- 35 - 115.6031.0

Be certain to orient the support flange so that the inlet and outlet connections of the vaporizing chamber are

located in their original position. However, do not reconnect the removable pipe sections at this point.

If the Vaporizer is equipped with cathodic protection, it is recommended that the magnesium rods be replaced

at this time.

If the electric immersion heater was removed for cleaning, inspect the gasket prior to reassembly and replace the

gasket if necessary.

When replacing the heater gasket(s), torque the bolts with dry lubed threads evenly in a crisscross star pattern to

a torque of 30 Ft-lbs.

15) Fill the water chamber to operating level, restore power to the control circuits and heater, and bring the

Vaporizer up to operating temperature.

16) Reconnect the supply of dry compressed air or nitrogen to the Vaporizer inlet connection and turn on the air

to purge the vaporizing chamber of all moisture. Then turn off and disconnect the air supply. Reconnect the pipe

sections, being certain to install new gaskets in each of the joints.

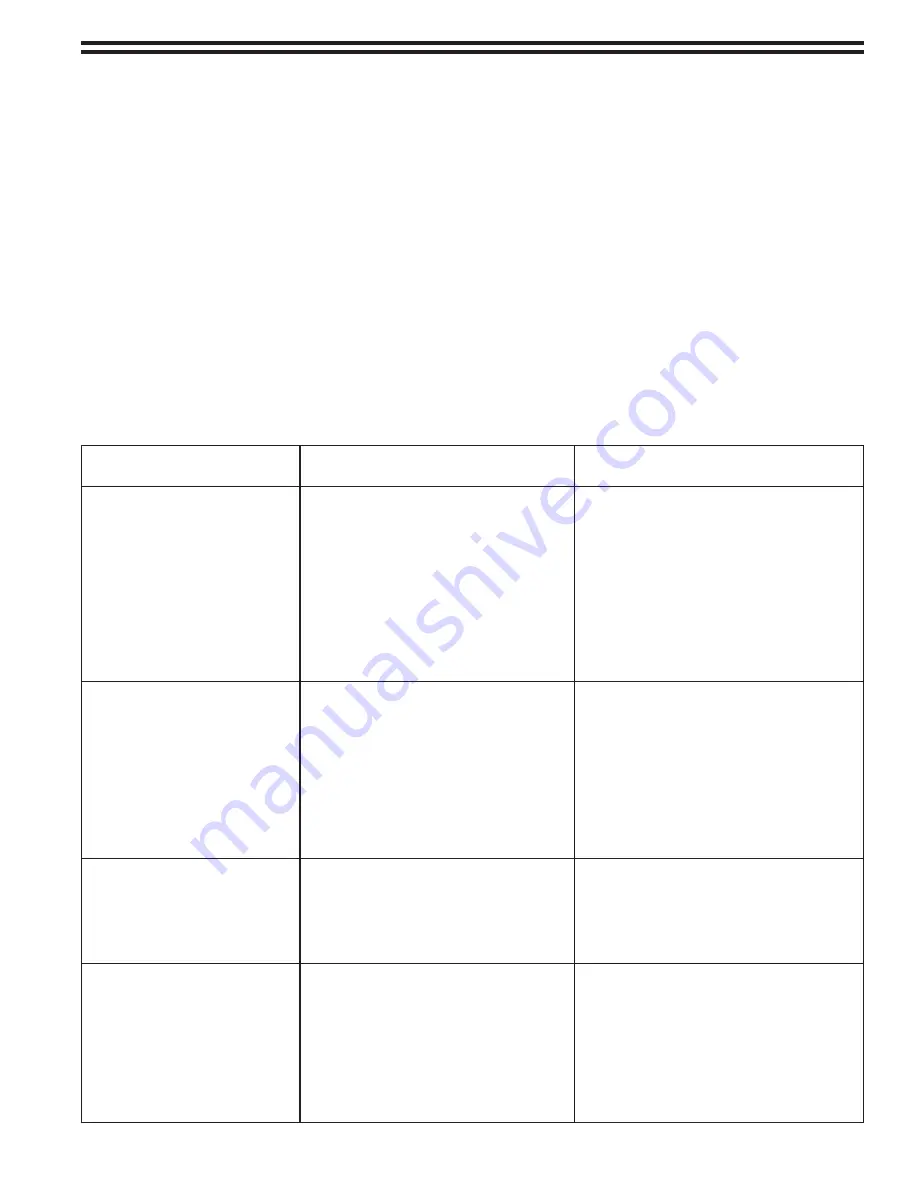

TABLE 4-1 TROUBLESHOOTING CHART

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Minimum recommended water

temperature (i.e., 15°F below

setting on water temperature

controller) cannot be achieved

and/or maintained as

evidenced by: a) gas flow being

shut off by closure of pressure

reducing and shut-off valve, b)

water low temperature alarm

being energized.

1. Electric immersion heater defective.

2. Magnetic heater contactor defective.

3. Surfaces of heater elements of

electric immersion heater fouled.

1. Check continuity of heater elements.

2. Check operation of holding coil and

contacts.

3. Shut down the Vaporizer, as described

under Section 3.10, remove the heater

and clean the elements.

Upon reassembly inspect and replace

the heater gasket, if necessary.

Maximum recommended

water temperature (i.e.,

15°F above setting on water

temperature controller) is

exceeded as evidenced by:

a) water observed to have

reached its boiling point,

b) water high temperature

alarm being energized.

1. Magnetic heater contactor

contacts fused.

1. Replace contacts.

Water level below normal

as evidenced by: a) visual

observation of sight glass of

water level gauge, b) low water

level alarm being energized.

1. Y-strainer in water supply line to

water supply piping assembly dirty.

2. Improperly set water level control

switch or faulty solenoid valve.

1. Clean Y-strainer

2. Reset switch or replace valve, as

required.

Gas pressure exceeds setting

on pressure relief valve as

evidenced by: a) gas being

discharged from the terminus

of the emergency and servicing

vent line,

b) vent alarm being energized,

c) pressure switch tripped.

1. Vaporizer isolated by valve closure.

2. Faulty pressure regulator in air

supply line to air padding system.

3. Rupture disk leaking.

1. Open valve after ascertaining the

ability of the system to receive

pressurized gas.

2. Replace regulator.

3. Replace rupture disk.

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

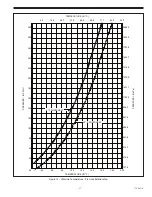

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

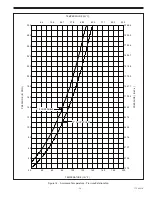

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...