- 5 -

115.6031.0

SAFETY SUMMARY

GENERAL

WARNINGS:

POSSIBLE PROCESS UPSETS:

Maintenance must be performed only by qualified personnel and only after securing equipment

controlled by this product. Adjusting or removing this product while it is in the system may upset

the process being controlled. Some process upsets may cause injury or damage.

RETURN OF EQUIPMENT: All equipment being returned to De Nora Water Technologies for repair

must be free of any hazardous materials (acids, alkalis, solvents, etc.). A Safety Data Sheet (SDS) for

all process liquids must accompany returned equipment.

Contact De Nora Water Technologies for authorization prior to returning equipment.

INSTRUCTION MANUALS: Do not install, maintain or operate this equipment without reading,

understanding and following the proper instructions and manuals, otherwise injury or damage

may

result.

ELECTRICAL SHOCK HAZARD: Equipment powered by AC line voltage presents a potential electric

shock hazard to the user. Make certain that the system power is disconnected from the operating

branch circuit before attempting electrical interconnections or service.

SPECIFIC

WARNINGS:

All components of the Vaporizer System are constructed of materials capable of withstanding the

corrosive action of the particular gas for which the System has been specified for service. Never use

any component for handling a gas different from which it has been purchased.

Modifying any of the factory-programmed operating functions from their factory pre-set settings

may result in improper and/or unsafe operation of the Vaporizer.

Do not install a valve between the gas discharge of the Vaporizer and the pressure relief valve.

ELECTRICAL SHOCK HAZARD: AC powered electrical equipment presents a potential shock

hazard. Installation and servicing should only be performed by qualified personnel.

Potable water is the only acceptable heat transfer medium. No other fluid is to be used!

Breakage of a chemical pipe, valve or fitting can cause a major hazardous chemical spill.

Never tighten or adjust any leaking fitting when the chemical supply cylinder valve is open.

System leaks and the procedures required to find leaks may cause exposure to hazardous chemicals

at levels that exceed Occupational Safety and Health Administration (OSHA) limits. It is the

employer’s responsibility to insure that proper equipment and procedures are used to limit the

employee’s exposure to the safe levels listed by OSHA. It is imperative that the superheat be

maintained at or above the minimum specified value for the gas in question.

A lesser value is indicative that the level of liquid chemical in the vaporizing chamber is above a

safe operating level. Under no circumstance should the gas outlet valve and an upstream liquid

valve be closed trapping liquid chemical in the Vaporizer chamber.

Maintenance steps 11, 12 and 13 must be performed outdoors or in a well ventilated area.

Summary of Contents for Capital Controls 71V3B Series

Page 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

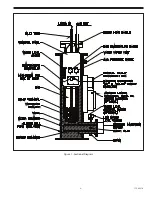

Page 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

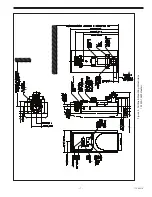

Page 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

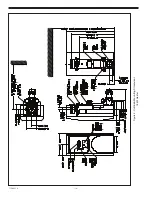

Page 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...